Solutions for Highly Abrasive Processes

Flow-Optimized Geometries and Materials as Solutions against Wear

Wear – Cost Driver Number One

In many industries, such as ore and metal processing, building materials or pigment chemistry, and salt and fertilizer manufacturing, abrasive wear leads to frequent plant downtime and the cost of repairing and replacing worn components. In applications with high product purity requirements – examples being the production of high purity silicon or toothpaste – traces of metals from the eroded steels can already lead to unacceptable contaminants and rejection of a product.

Wear Protection Pays Off

Every effective measure to extend the service life while stirring abrasive media pays off, in many cases after just a few weeks. Avoiding downtime is often much more serious than the mere cost of repair and replacement. EKATO has the know-how to determine the causes of wear in tests or through flow simulations and to derive appropriate measures: service life extensions from up to even more than 20 times are possible.

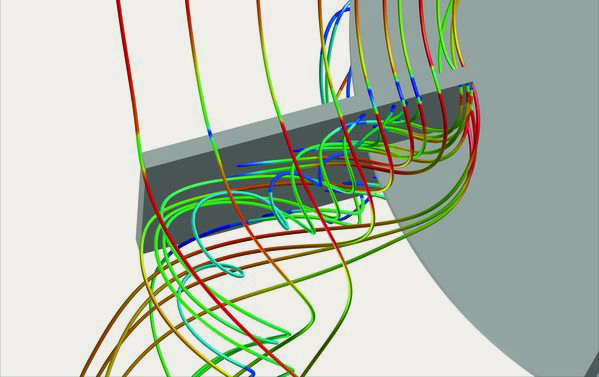

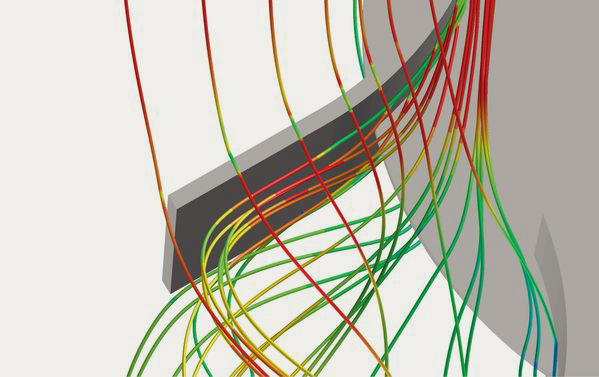

Flow Optimization

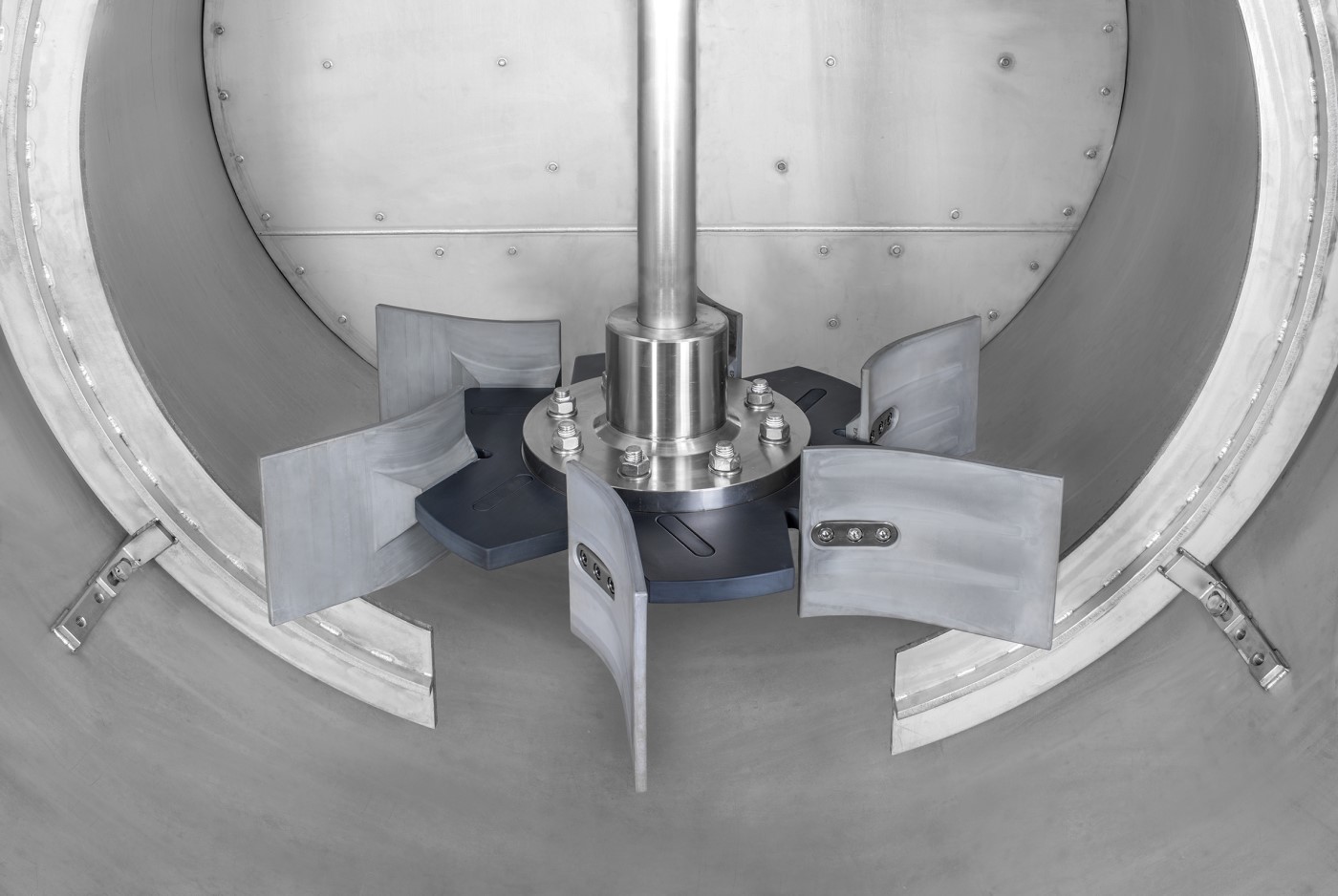

An elegant approach are flow-optimized impellers, since vortex shedding on the impeller blades especially increases the aggressive impact wear. If the flow separations can be reduced, the service life becomes longer without further measures: more than twice this is easily possible.

Coatings

Coatings must be very carefully matched to the operating conditions and the materials involved. The disadvantage of coatings: if the thin protective layer is penetrated by a comparatively small abrasion at one point, the wear in the base material underneath can proceed unhindered.

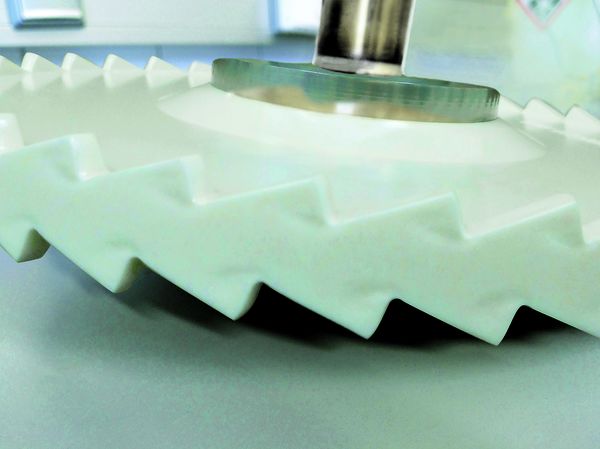

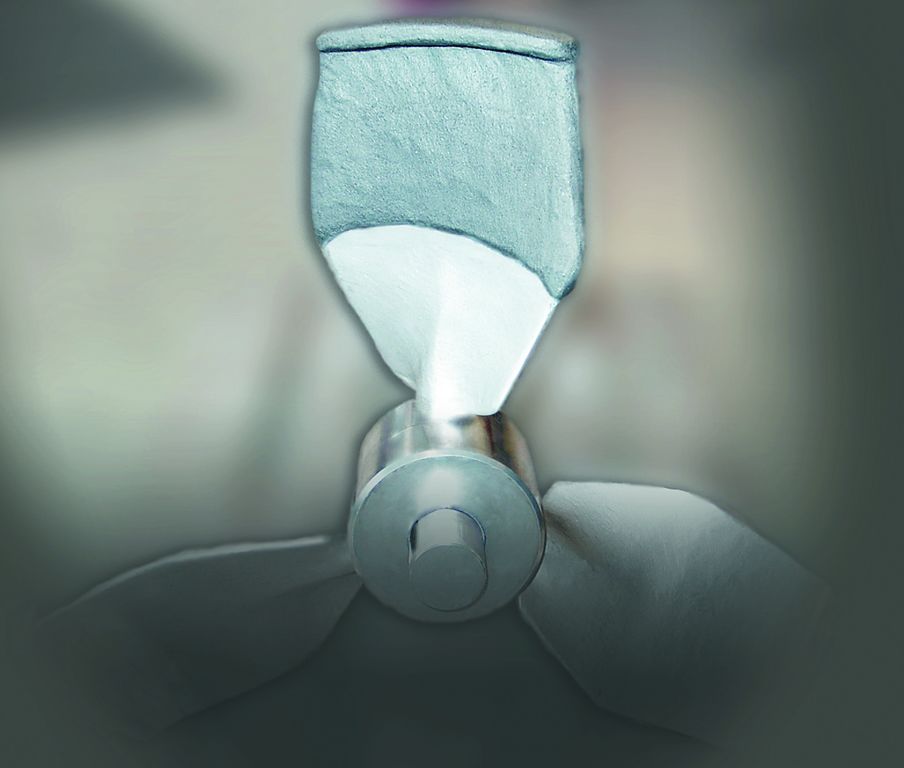

Ceramic Materials

Modern engineering ceramics open up completely new perspectives. Advances in ceramic processing allow the construction of impellers with diameters of 2 m and more. Even complex geometries can be realized. Depending on the size and shape of the impeller, it can be designed as one solid ceramic part, or alternatively ceramic impeller blades are connected to a metallic hub. This composite construction is permissible since wear always occurs in the area of the highest speeds, which is on the outer edge of the impeller.

Know How as a Prerequisite for Success

Ceramic materials have a number of excellent properties. They combine high chemical resistance with extreme hardness, both of which guarantee long service life. Their strength characteristics remain constant even at high temperatures. However, the design principles must be adapted to the material ceramic. Manufacturing tolerances are narrower than in the classical apparatus and plant engineering, and the different thermal expansions of steel and ceramic must be taken into account. A team of EKATO specialists constantly adapts the know-how for calculating and manufacturing the components to new requirements. For this purpose, the tools of finite element analysis are available as well as the possibility to put prototypes realistically to a long-term test. In the EKATO Test Center, a wide variety of vessels up to 100 m³ and 500 kW agitator power are available for specific applications.