EKATO

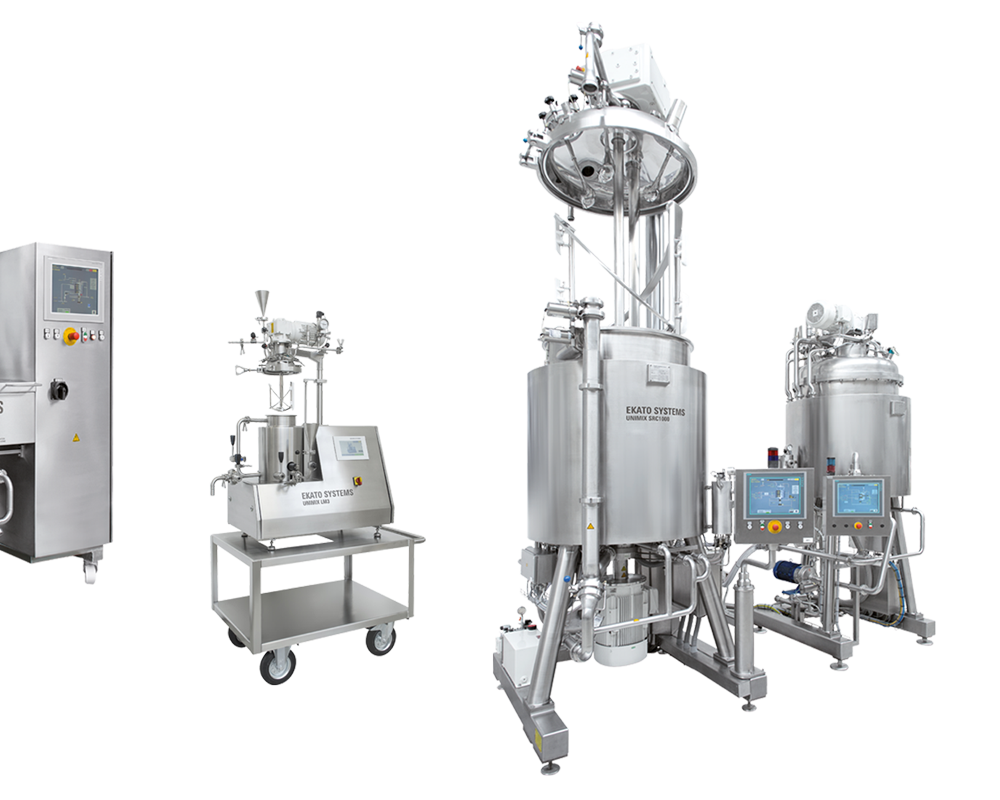

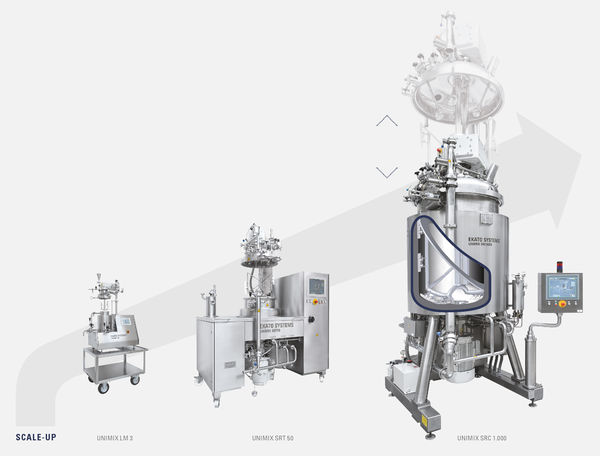

Vacuum Processing Units in Lab Scale – UNIMIX

Production of New Recipes and Small Batches

EKATO UNIMIX laboratory and pilot plant mixers for the cosmetic and pharmaceutical industry.

Laboratory Mixer Type UNIMIX LM

The UNIMIX LM laboratory type mixer is used to record important data during product development, which represent a reliable basis for later production (scale-up). All parameters such as speed, temperature and pressure can be adjusted variably. The homogenizing system of the laboratory mixers is a particular advantage since it is not only used for internal and external homogenization, but also for emptying and as a cleaning pump. This small "plug-in" system is available as a 3 or 6 liter version.

| Type | Effective volume [l] | Length [mm] | Width [mm] | Height, closed [mm] | Lid open [mm] | Net weight [kg] |

|---|---|---|---|---|---|---|

| LM 3 | 1 – 3 | 885 | 480 | 1100 | 1260 | 160 |

| LM 6 | 2 – 6 | 885 | 480 | 1100 | 1360 | 174 |

Pilot Plant Mixer Type UNIMIX SRT

The same advantages and a similar design are offered by the UNIMIX SRT pilot plant series. The SRT system is designed for product and process development (scale-up) in the pharmaceutical and cosmetic industry and is ideally suited for the production of small product batches (sizes between 15 and 70 liters) of creams, ointments, gels, toothpaste, mascara, etc.

| Type | Effective volume [l] | Length [mm] | Width [mm] | Height, closed [mm] | Max. lid open [mm] | Net weight [kg] |

|---|---|---|---|---|---|---|

| SRT 15 | 15 | 1760 | 810 | 1550 | 500 | 700 |

| SRT 25 | 25 | 1760 | 810 | 1600 | 500 | 800 |

| SRT 50 | 50 | 1860 | 1010 | 1880 | 600 | 1000 |

| SRT 70 | 70 | 1860 | 1010 | 2000 | 700 | 1200 |

The UNIMIX laboratory and pilot mixers can be tested in the EKATO SYSTEMS laboratory in Schopfheim, Germany, and are also available as renting machines. From the laboratory, through pilot till production units: EKATO is your partner for reliable scale-up calculations.

Features

- Production of small batches under production conditions

- Ideal product results during radial and axial mixing through the PARAVISC agitator

- No additional pump for discharging the product (homogenizer is used as CIP pump)

- Reduction of process times with the highest product quality

- Available as a rental machine, suitable for tests at any time