EKATO

Vacuum Dryer – SOLIDMIX

Vertical Industrial Dryer from Pasty to Free Flowing

The high-quality SOLIDMIX vacuum dryers are produced with state-of-the-art machines and tools as well as highly trained and experienced staff.

The drying of solids is an elementary process step for various productions. In many processes, the mechanical separation of solids by decanter, filter press or centrifuge is followed by a thermal drying step. EKATO SYSTEMS has developed two apparatuses to cover various solids applications.

Table of Contents

Product Details

For free-flowing products, the SOLIDS-PARAVISC impeller is used in the SOLIDMIX VST dryer series. The ISOPAS impeller was designed for processing pasty, poorly flowing media. It is implemented in the EKATO SOLIDMIX VPT dryers. The modular system can also be specifically tailored to customer requirements. Our experienced experts help to provide the vacuum dryer with the appropriate process technology solution. The following basic operations are available: drying, mixing, chemical reactions, coating, granulating, heating, cooling, moistening, and many more. The EKATO SOLIDMIX vacuum dryer typically has the following system components:

The EKATO SOLIDMIX systems have the same design – from laboratory to production scale. Depending on the type of installation, 3 – 32,000 l can be used.

- Mixing impeller (patented EKATO ISOPAS or EKATO SOLIDS-PARAVISC)

- ASME, PED, or SELO vacuum and pressure vessel

- Vacuum system

- Solvent recovery system

- Automation

- Heating and cooling system

- Cleaning in place (CIP) cleaning system

Features

- Agitators designed for minimum power input with maximum vertical mixing (energy efficiency)

- Gentle vertical mixing with minimal shear

- Homogeneous temperature distribution and heat transfer in the loose bulk

- Dryers optimized for maximum discharge during emptying

Vertical Dryer for Solids Type SOLIDMIX VST (100 L to 32,000 L)

The SOLIDMIX VST vacuum dryer with the PARAVISC impeller for solids is particularly suitable for drying free-flowing goods and bulk goods. Because of the free-overhung shaft, no bearings are in contact with this product. This offers great advantages in the processing of fine chemicals, pharmaceutical products, or foodstuffs. In addition, the small wall clearance between the impeller and the vessel wall prevents product residues. The conical bottom ensures that only the smallest amounts of residue remain in the dryer.

Optionally for the SOLIDMIX VST various system components can be offered. For example:

- Filter for separating the exhaust vapors

- Heatable agitator shaft

- Sampling ports

- Temperature measurement

- CIP-systems

- ATEX versions from Zone 0 to Zone 2

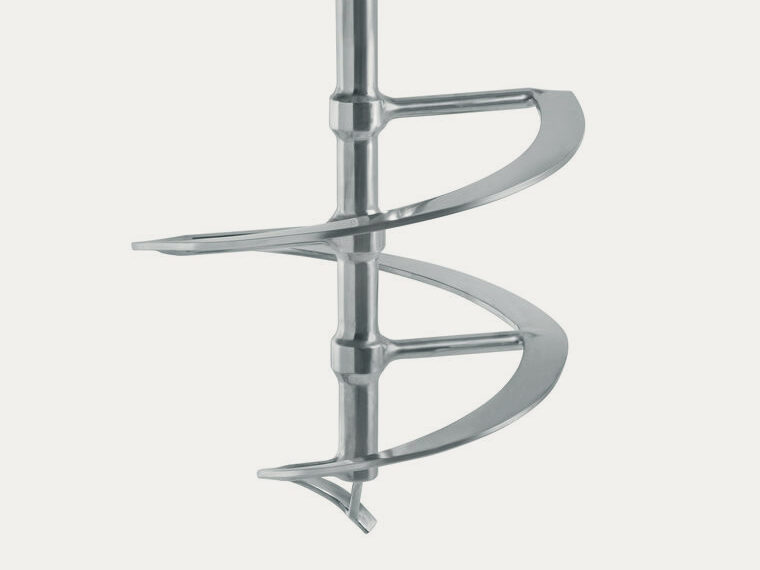

EKATO SOLIDS-PARAVISC

The PARAVISC impeller for solids, especially designed for the SOLIDMIX VST vacuum dryer, enables reliable operation and low maintenance. The vertical product circulation results in an optimized heat exchange. The impeller movement creates a permanent exchange at the vessel surface. In addition, the product is gently mixed at minimal shearing. Thanks to a special design, the mixing unit ensures homogeneous temperature distribution and thus has a direct effect on product quality and process times.

| Type | Effective volumes [l] | Height H [mm] | Width W [mm] | Weight [kg] |

|---|---|---|---|---|

| VST 100 | 110 | 2000 | 1100 | 1000 |

| VST 250 | 260 | 2500 | 1300 | 1500 |

| VST 400 | 430 | 2700 | 1500 | 2000 |

| VST 630 | 670 | 3100 | 1700 | 3000 |

| VST 1000 | 1110 | 3400 | 1900 | 4000 |

| VST 1600 | 1710 | 3800 | 2100 | 5000 |

| VST 2500 | 2500 | 4200 | 2300 | 6000 |

| VST 4000 | 4090 | 4800 | 2700 | 9000 |

| VST 5000 | 5450 | 5000 | 2700 | 10000 |

| VST 6300 | 7090 | 5600 | 2400 | 12000 |

| VST 10000 | 10080 | 6200 | 3600 | 14000 |

| VST 16000 | 16840 | 6900 | 4100 | 16000 |

| VST 20000 | 20220 | 7400 | 4800 | 18000 |

| VST 25000 | 26090 | 8000 | 5200 | 20000 |

| VST 32000 | 33010 | 8500 | 5600 | 25000 |

Vertical Process Dryer Type SOLIDMIX VPT (50 L TO 5,000 L)

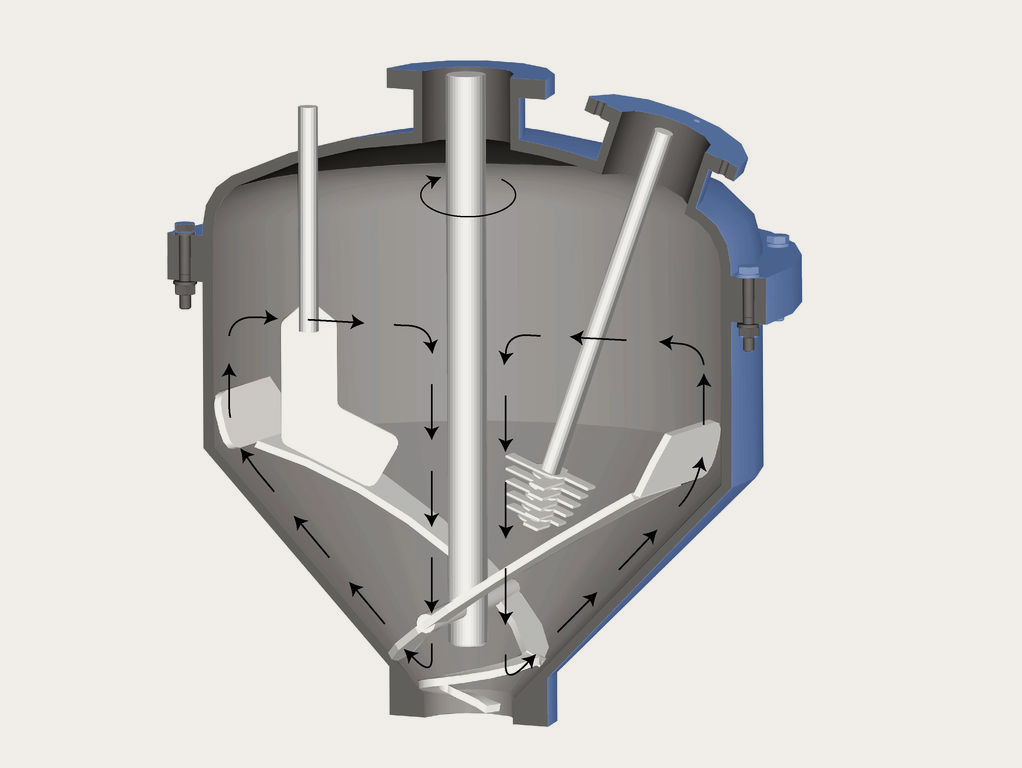

The vertical dryer of the SOLIDMIX VPT series, featuring the EKATO ISOPAS impeller especially developed for the processing of pasty and poorly flowing media, ensures intensive mixing.

In addition to its special geometry, the EKATO SOLIDMIX VPT process dryer is equipped with a baffle that prevents co-rotation of the product and ensures homogeneous mixing – even with critical flow characteristics. With the EKATO SOLIDMIX VPT unit, it is possible to include a temperature sensor in the conical part of the vessel plus another sensor into the baffle in order to record elementary process parameters directly inside the product. GMP-compliant design is ensured. It is also possible to take samples without interrupting the process and integrate a chopper for breaking up agglomerates. With a chopper, drying time is shortened because of the increased surface of the particles (shorter diffusion paths for the solvent).

Optionally for the SOLIDMIX VPT vacuum dryer, various system components can be offered. For example:

- Flow elements (e.g., choppers or baffles)

- Heatable agitator shaft

- Sampling

- Temperature measurement

- Filter for separating the exhaust vapors

- CIP-systems

- ATEX versions from Zone 0 to Zone 2

EKATO ISOPAS

The EKATO ISOPAS impeller system ensures good circulation as well as efficient and effective axial mixing with low power input. Because of the optimal shape of the blade and the minimal use of metal, as well as the conical bottom, there is only minimal residue after emptying.

The smallest possible wall clearance ensures an efficient heat transfer. This drastically reduces mixing times.

| Type | Effective volumes [l] | Height H [mm] | Width W [mm] | Weight [kg] |

|---|---|---|---|---|

| VPT 50 | 50 | 2000 | 1000 | 800 |

| VPT 100 | 100 | 2100 | 1100 | 1000 |

| VPT 250 | 250 | 2300 | 1500 | 1500 |

| VPT 400 | 400 | 2500 | 1800 | 2000 |

| VPT 630 | 630 | 3100 | 2000 | 3000 |

| VPT 1000 | 1000 | 3300 | 2200 | 4000 |

| VPT 1600 | 1600 | 3600 | 2400 | 5000 |

| VPT 2500 | 2500 | 3800 | 2700 | 6000 |

| VPT 4000 | 4000 | 4500 | 3100 | 7000 |

| VPT 5000 | 5000 | 50000 | 3400 | 9000 |