Petrochemical

Agitators for Storage Tanks (Crude and Refined Oil)

Oil Keeps the World Moving

…and EKATO is at the mix in terms of mobility, heat, petrochemicals, lubricants and bitumen.

In oil storage tanks, EKATO relies on proven technology and can build on more than 85 years of experience. On request, the design can also be confirmed by CFD (Computational Fluid Dynamics) numerical flow simulation.

For mixing tasks like effective mixing of crude oil considering and controlling the sand and water content, BS&W (bottom sludge and water / base sediment and water), mixing of different crude oils, a constant temperature distribution in the tank or for the mixing of refined oils, EKATO provides the appropriate solutions.

Portfolio

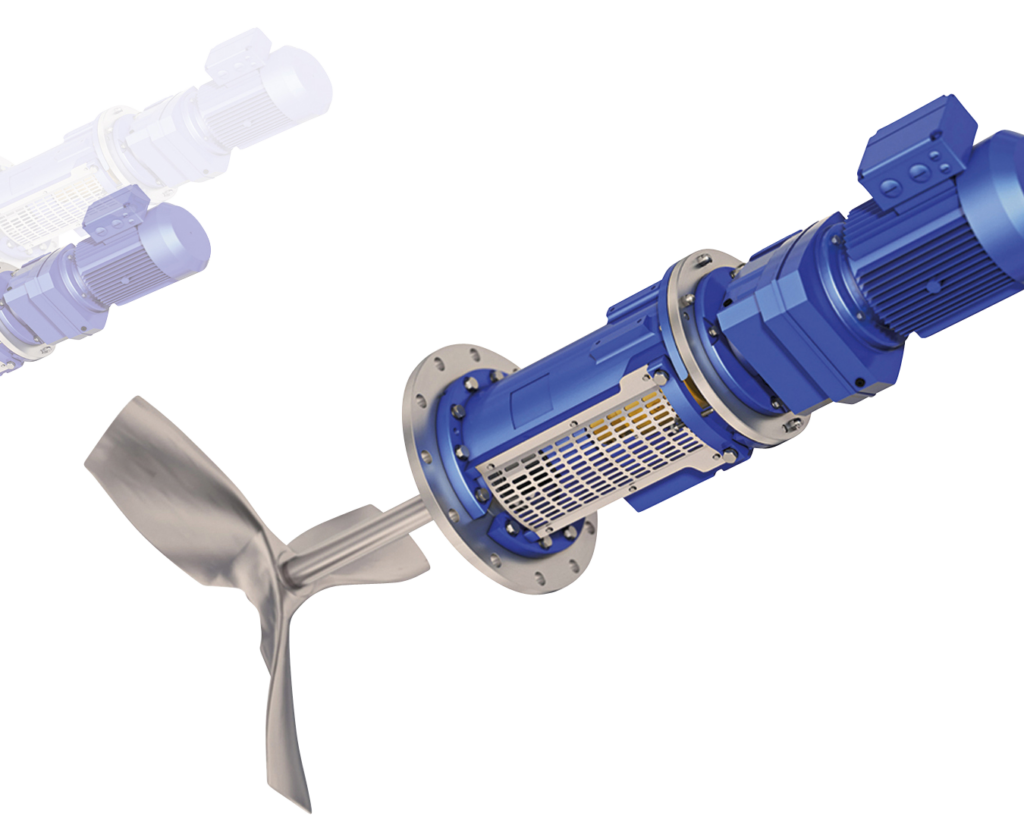

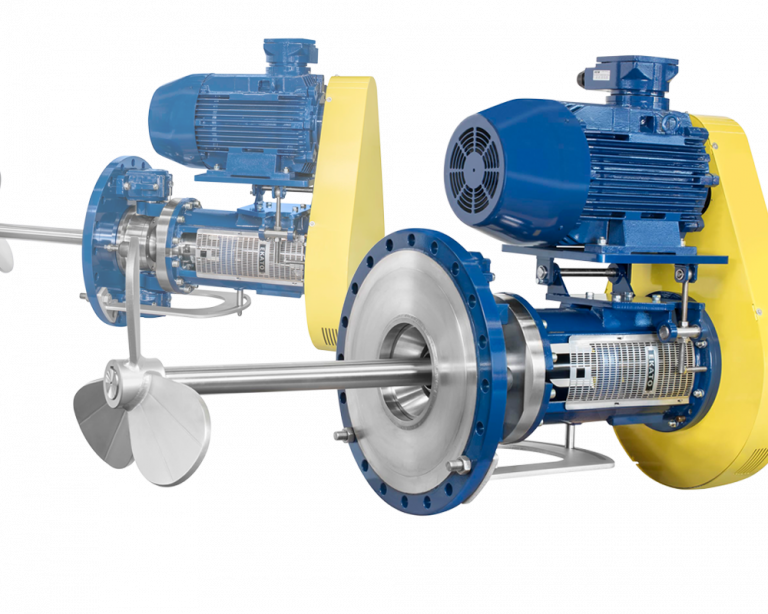

EKATO Side-Entry Agitator ES 2000 SW

The swiveling EKATO side-entry agitator for crude oil storage tanks is a compact, state-of-the-art technology. It uses a single or double mechanical seal system according to API 682, modified for agitators. It represents a reliable solution for the oil and petrochemical industry. Manual adjustment on site or automatic positioning in the process control system (PCS) are available options to swivel the agitator.

Optimal Plant Operation

The decisive factors for trouble-free operation of the agitators are:

- Optimal alignment at the vessel wall

- Impeller stream length

- Pumping capacity of the impeller

Our operational experience in the field of side-entry agitators, together with computational fluid dynamics (CFD) simulations, allows us to determine the optimum number and orientation of agitators around the tank circumference. Reliable, easy-to-maintain, and economical operation are the main benefits based on our knowledge and know-how of side-entry agitators.

Swiveling toothed belt design

- Antistatic high torque drive (HTD) toothed belt

- Shut-off device with positive locking (clamping flange), for maintenance or seal replacement with filled vessel, max. 7 bar (abs.)

- EKATO mechanical seal in cartridge design, modified for agitators

- Swiveling device, manual or automatic adjustment

- High efficiency impeller (EKATO propeller)

- Product wetted material in stainless steel, in accordance with NACE

| Motor Power | 7,5 - 55 kW |

| Shaft Diameter | 60 - 100 mm |

| Operating Pressure | Atmospheric - liquid column |

| Approval | ATEX 2014/34/EU, EAC TR-ZU 010/012-2011 approval |

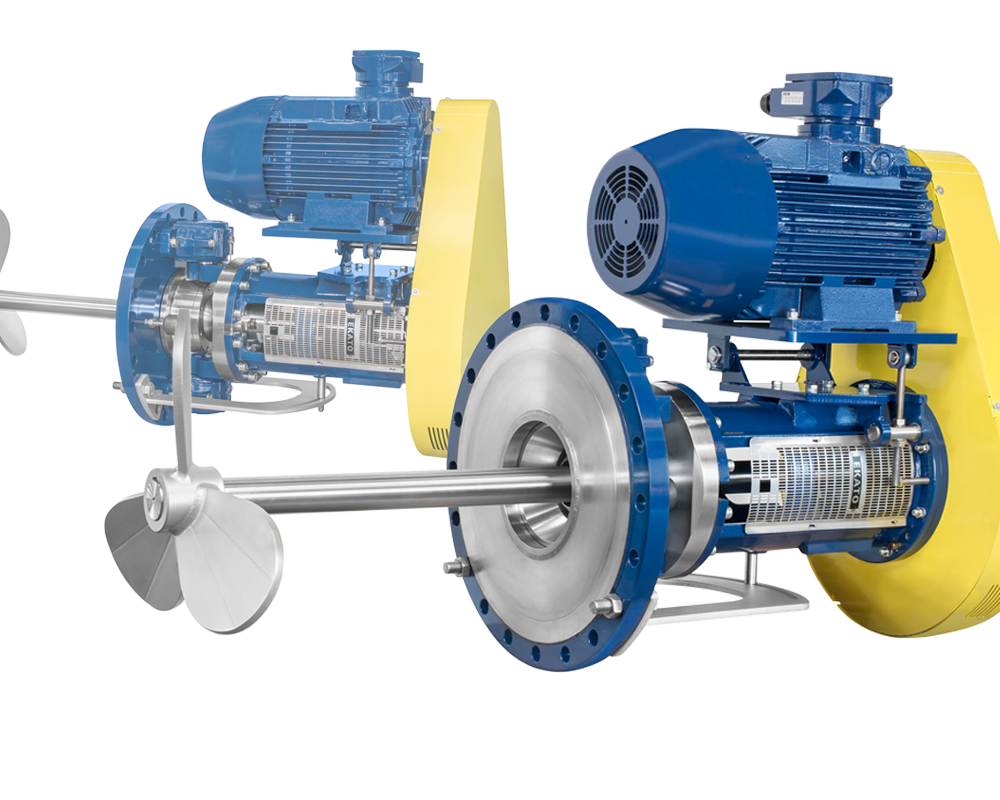

EKATO Side-Entry Agitator ES 2000 / ES 2000 Z

Fixed toothed belt design

- Antistatic high torque drive (HTD) toothed belt

- Shut-off device with positive locking (clamping flange), for maintenance or seal replacement with filled vessel, max. 7 bar (abs.)

- EKATO mechanical seal in cartridge design, modified for agitators

- Optionally with adapter flange design

- High efficiency impeller (EKATO propeller)

- Product wetted material in stainless steel, in accordance with NACE

| Motor Power | 7,5 - 55 kW |

| Shaft Diameter | 60 - 100 mm |

| Operating Pressure | Atmospheric - liquid column |

| Approval | ATEX 2014/34/EU, EAC TR-ZU 010/012-2011 approval |

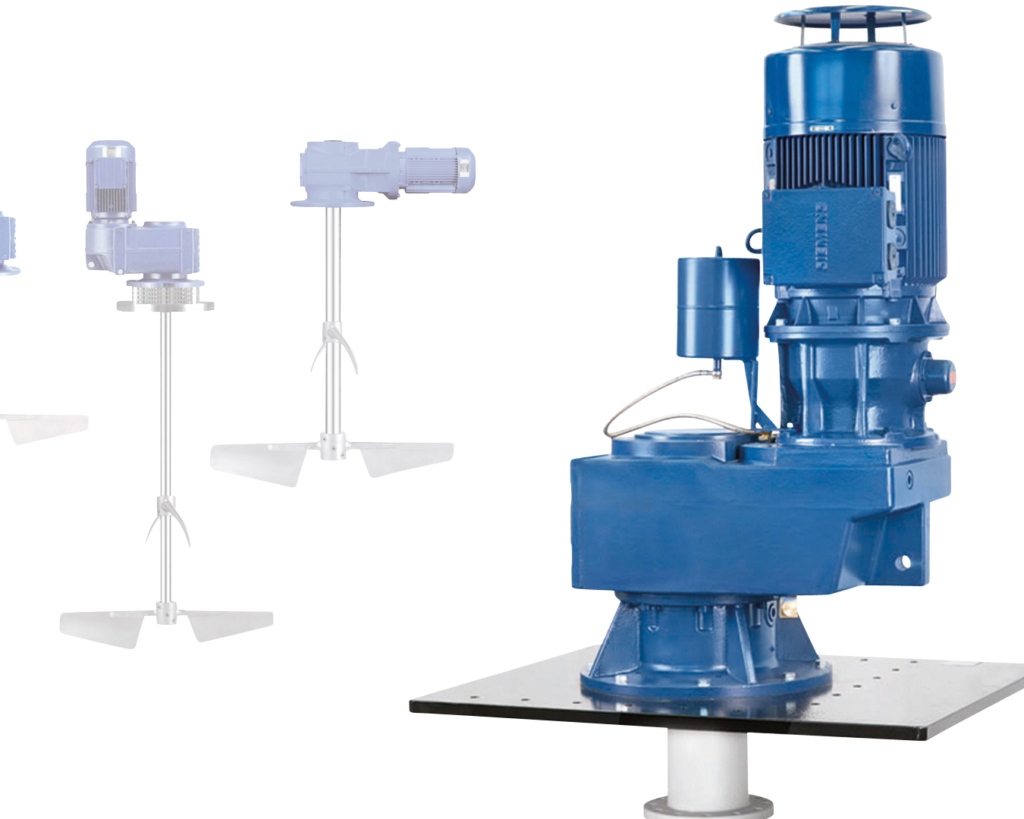

Fixed Gearbox Design ES 2000

The design with a gearbox is available for motor power ranges from 3 – 22 kW and larger diameters of the agitator.

Agitator design

- Motor with various gear units

- Shut-off device with positive locking (clamping flange), for maintenance or seal replacement with filled vessel, max. 7 bar (abs.)

- EKATO mechanical seal in cartridge design according to API 682 publications, modified for agitators

- Optionally with adapter flange design

- High efficiency impeller (EKATO propeller)

- Product wetted material in stainless steel, in accordance with NACE

| Motor Power | 3 - 22 kW |

| Shaft Diameter | 40 - 80 mm |

| Operating Pressure | Atmospheric - liquid column |

| Approval | ATEX 2014/34/EU, EAC TR-ZU 010/012-2011 approval |

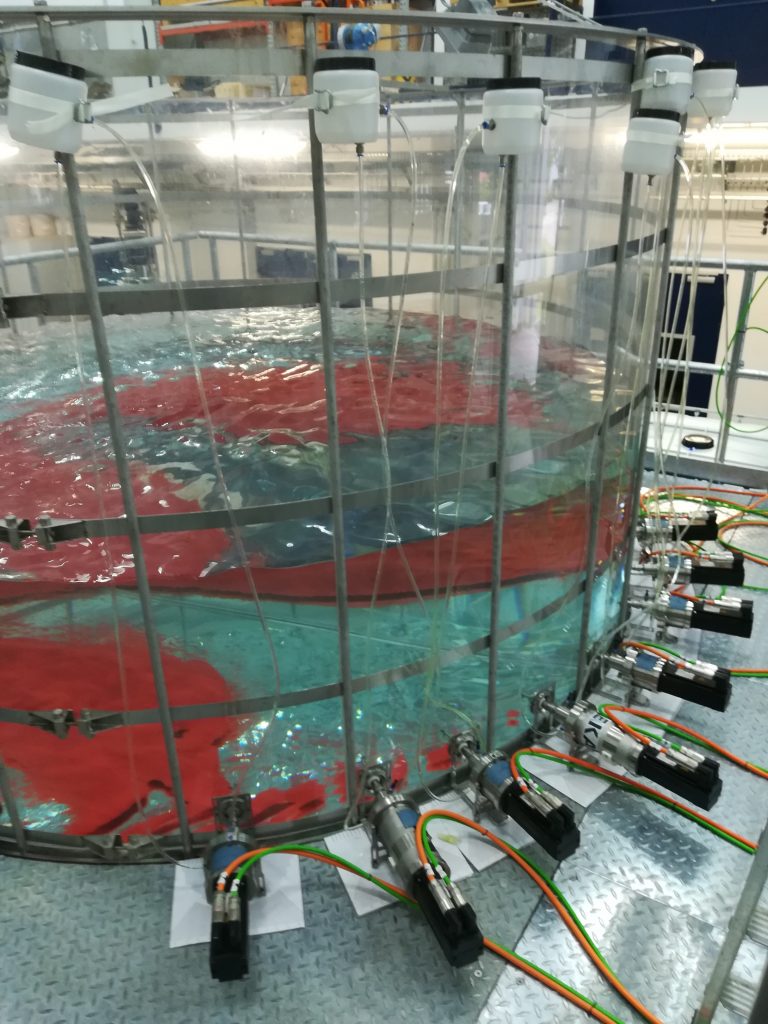

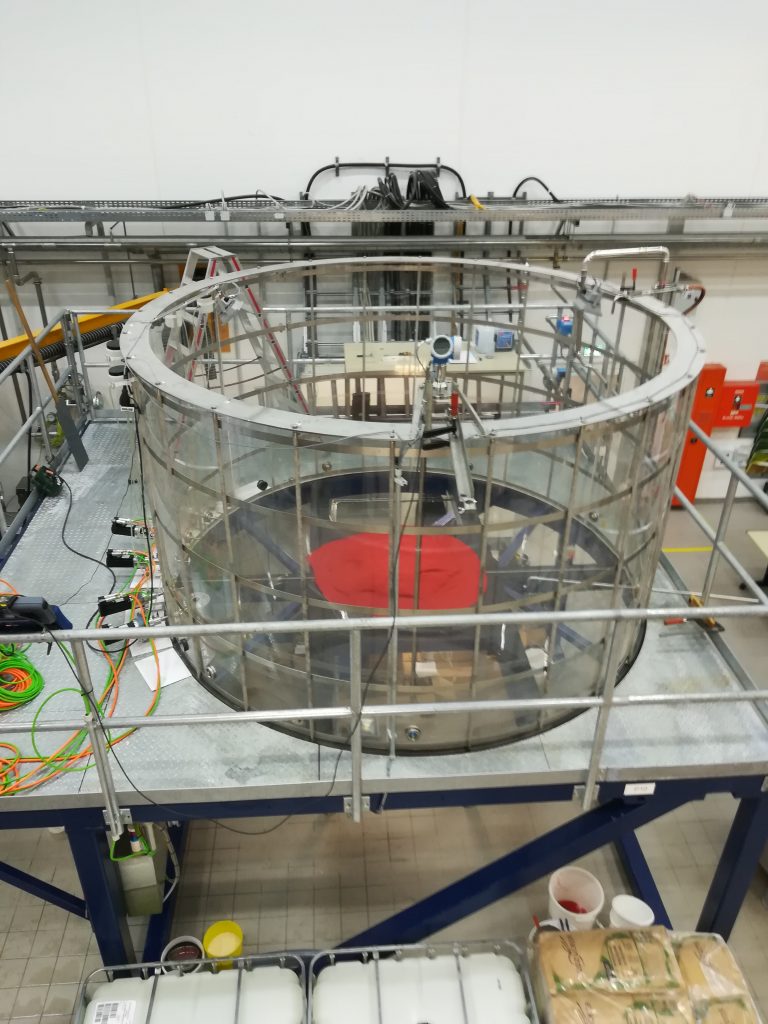

R&D Test Tank

With our new test tank with a tank diameter of 3.2 m, a height of 1.74 m and a total volume of 14 m³, an improved scale-up to operating scale has been realized. Up to 10 side-entry agitators can be operated, and the behavior of crude oil can be investigated in depth. Optionally, the scale-up design can be confirmed with a CFD analysis.