Industrial Photoreactors

New Syntheses by Stirred Photoreactors - Turnkey from One Source

Why Industrial Photochemistry?

A large number of chemical reactions are carried out at temperatures between 100 and 250 °C in order to achieve a fast reaction and thus high productivity. At these temperatures, however, decomposition processes already start with corresponding losses in yield and undesired by-products.

With the help of catalysts, reactions can be activated even at lower temperatures, but are expensive to procure and to handle. Photochemistry offers an elegant alternative and allows new syntheses. Not heat or catalysts, but the energy of light activates the reaction, which can then take place at temperatures well below 100 °C and often even at room temperature. By this process, decomposition or by-products are reduced to a minimum or do not arise at all. Light instead of heat, this principle can be applied to a variety of syntheses such as chlorinations, sulfonations, sulfoxidations or nitrosylations.

| Process | Product | Industry | Multiphase |

|---|---|---|---|

| Chlorination | Intermediates, Solvents, C-PVC, Rubbers | Specialties, Polymers | l-g, l-g-s |

| Bromination | Intermediates | Specialties | l |

| Sulfoxidation | Intermediates, Sulfonic acids, Surface active materials | Specialties, Consumer products, Polymers | l-g |

| Sulfochlorination | Intermediates, Sulfonic acids, Surface active materials | Specialties, Consumer products, Polymers | l-g |

| Nitrosylation | Intermediates, Nylon 6 and 12 | Specialties, Polymers | l-g-s |

| Oxidation | Intermediates, Surface active materials | Specialties, Perfumes, Pharmaceuticals | l, l-g, l-g-s |

| Isomerization | Intermediates | Specialties, Pharmaceuticals | l |

| Cycloaddition, electrocyclic reactions | Intermediates | Specialties, Pharmaceuticals | l |

| Polymerization | Polymers | Specialties, Polymers | l, l-g, l-g-s |

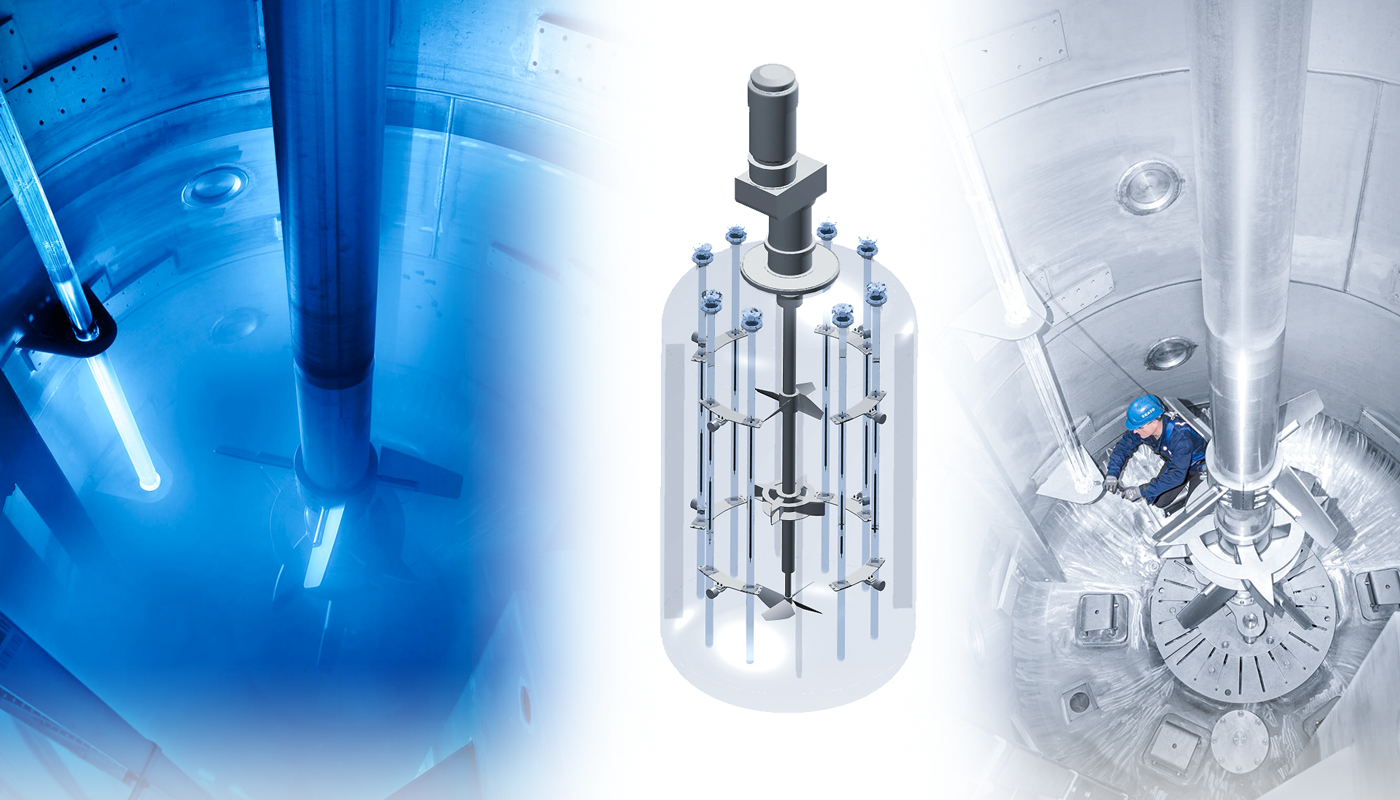

The Turnkey EKATO-Photoreactor

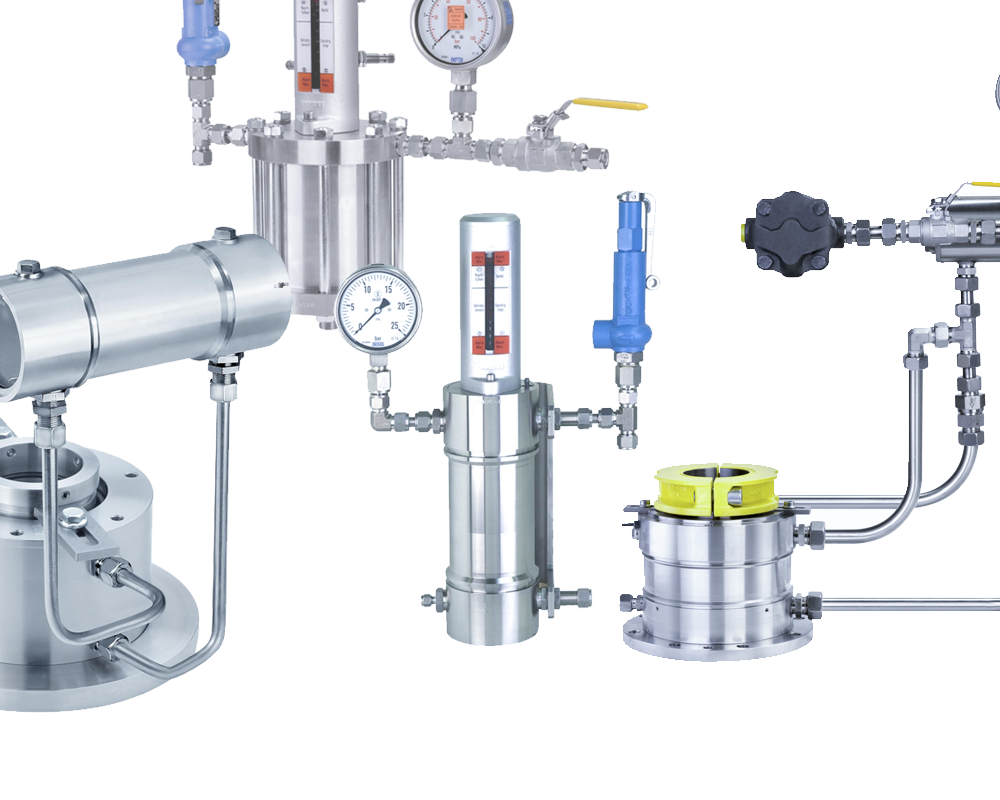

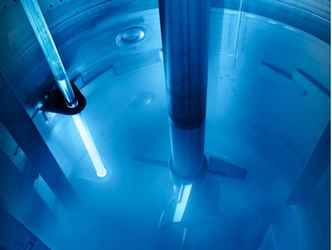

The UV Light Sources - Safe Operation

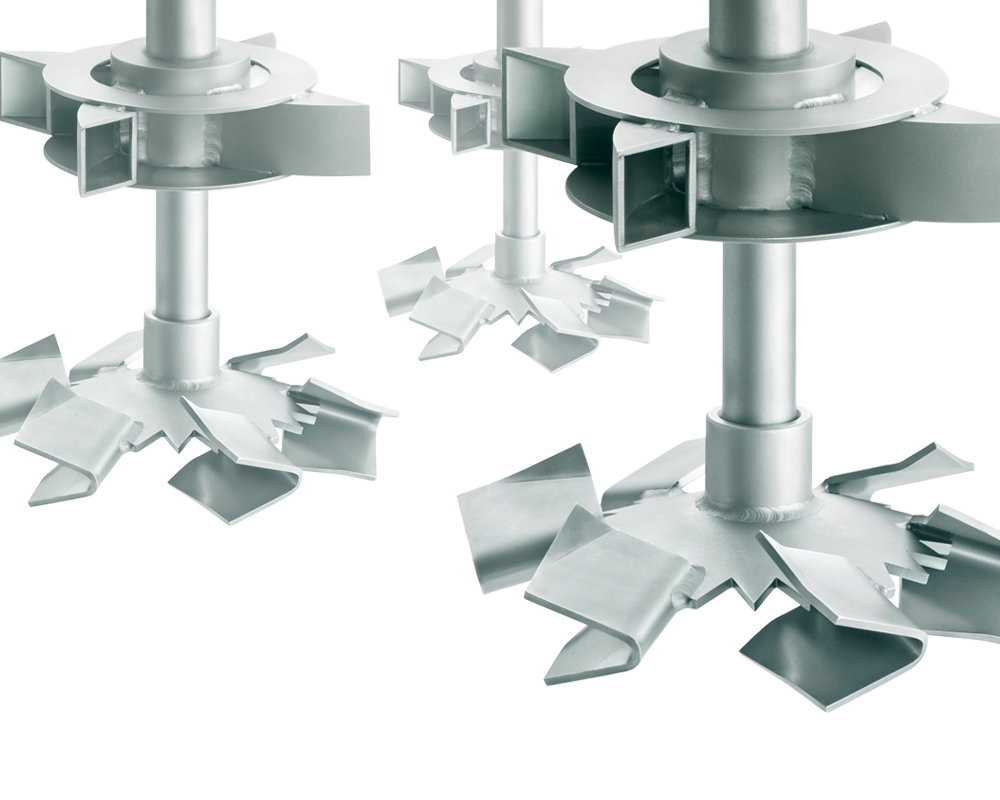

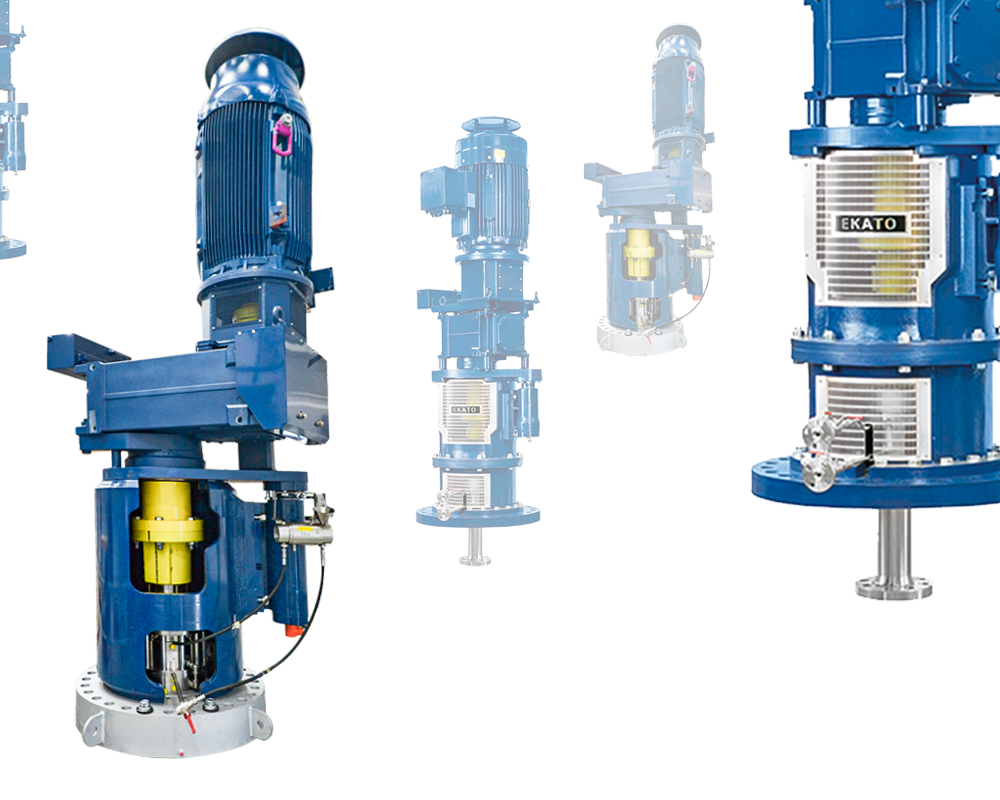

The Agitator System - High Circulation Rates Required

Overall Responibility as your Single-Source Supplier

From consulting and engineering to production and assembly: We offer all services related to stirred photochemical reactors for industrial applications. As a single-source supplier, EKATO takes the overall responsibility to manage your project through all project phases. Special know-how and many years of experience in the design and delivery of stirred reactors make us a competent partner – from the idea to the commissioning of a photochemical production plant.

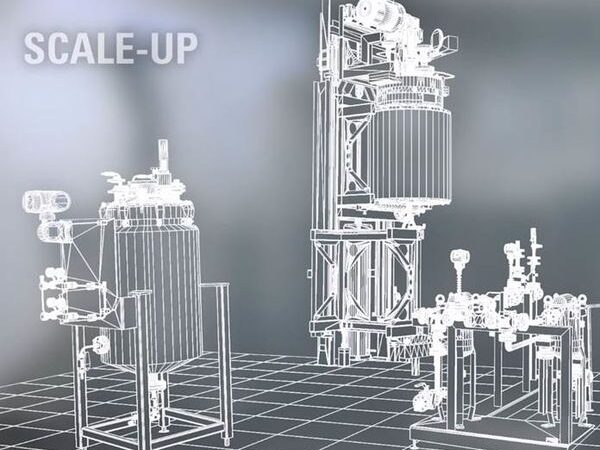

From the Laboratory to the Turnkey Production

Our Range of Services Includes

- Photochemical process consulting

- Physical and fluid dynamics simulation and calculation

- Performing optical measurements

- Tests in laboratory scale and pilot reactors (5 liter and 50 Liter)

- Scale-up and process engineering reactor design

- Reactor modeling by state-of-the-art CAE methods (CFD, FEM)

- Reactor engineering

- Delivery of the turnkey photochemical reactor

- Installation and commissioning

Our Customer Promise

Our aim is to consistently support our customers as a development partner and system integrator on the way from the idea to the photochemical production plant. As a single-source supplier, we assume overall responsibility for the design and delivery of the best reactor system for each individual customer process.

Everything works together perfectly to reduce friction losses and costs. We reduce the interfaces of our customers when planning a photochemical production plant to one point of contact.