EKATO

PARASEG

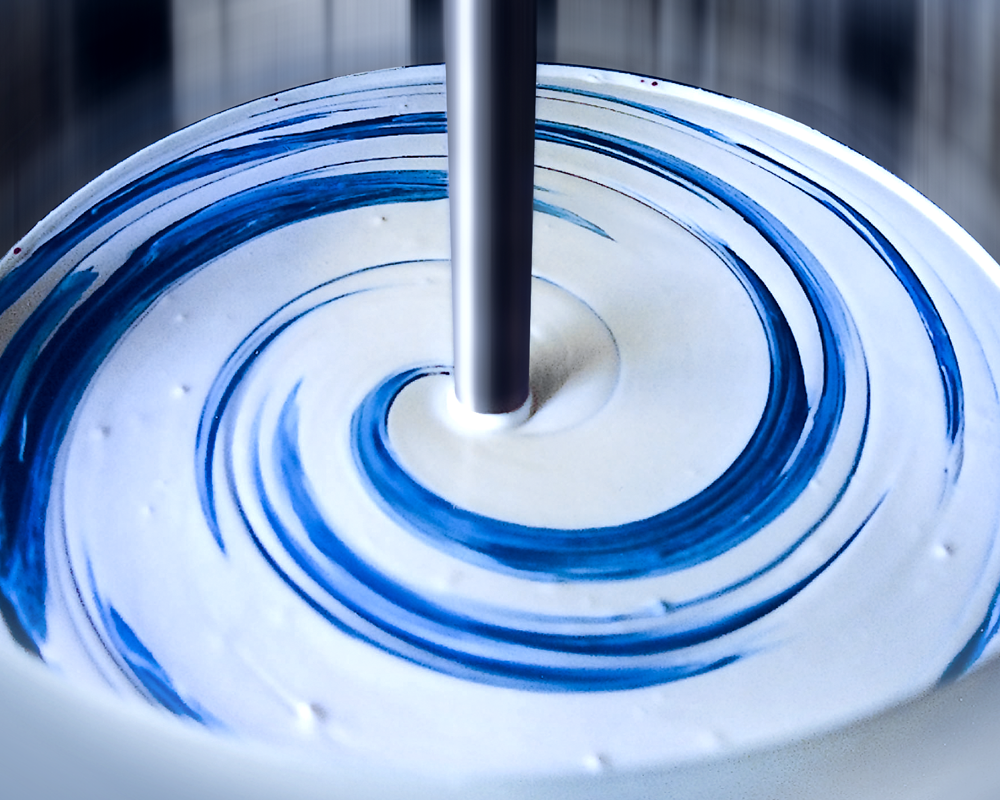

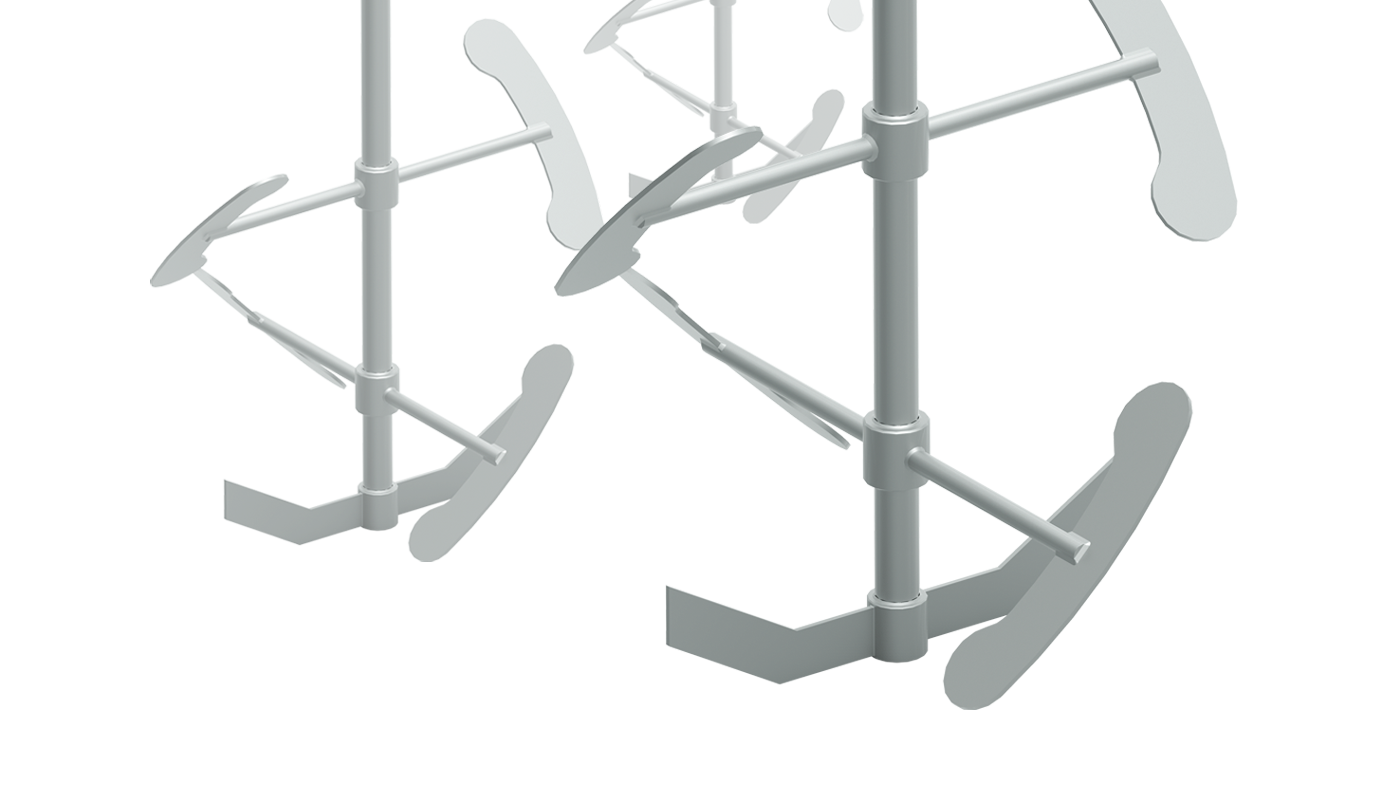

Close-to-Wall Impeller System, Ideal for Medium to High Viscosity

The EKATO PARASEG is specifically designed for mixing medium to high viscosity process stages. This impeller can be used within variable modular systems that offer several possibilities to fulfill a wide range of process tasks.

The EKATO PARASEG impeller system operates close to the vessel wall and is ideal for medium to high viscosity processes. The flexible set-up of the impeller system and the blade geometry offer several possibilities to fulfill a wide range of process tasks. Shorter blending times, a good heat transfer, quick incorporation of liquids and solids from the surface, de-agglomeration, de-aeration and a quick product discharge are just some of the tasks fulfilled by this mixing system. Batch time reductions of up to 50% can be achieved, compared to conventional counterflow impellers, because of a better pumping rate with the same motor power.

EKATO PARASEG Impeller for medium to high viscosity processes