Crystallization

Well-Controlled Particle Generation

Crystallization is a process step in a vast range of applications and industries such as chemicals, API production, food manufacturing and precipitation of ores. Depending on the process requirements, cooling, evaporation or precipitation is selected to form crystals. Accordingly, the variation of applied machines is numerous.

Loop-Crystallizers are often called Forced Circulation (FC) Crystallizers due to the fact that the solution is forced to flow by a pump while the crystallization in layers is a static process. In agitated services there are two main mixing systems. Either an open system with a hydrofoil impeller or a draft tube is utilized. EKATO provides highly efficient solutions, which do not end at the impeller itself.

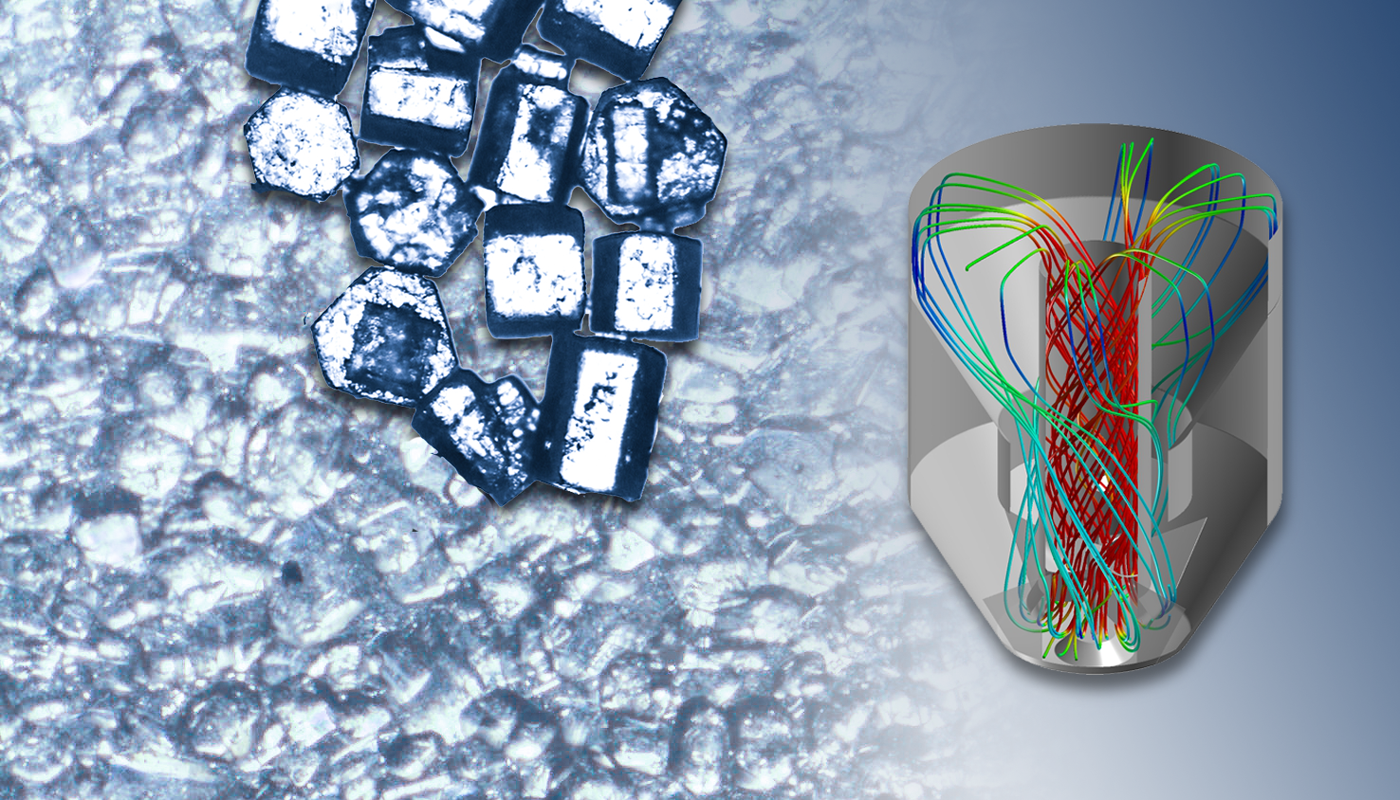

Example for crystallization products

- Potash

- Sugar

- APIs

EKATO is glad to assist you during the whole project starting from a first estimation until detail engineering, manufacturing and operation. EKATO has excellent experience in designing not only the agitators, but also can assist with expertise in vessel design and process know-how. Furthermore we can support with CFD simulations and trials in our laboratory or on site.

Batch Crystallization

Continuous Crystallization

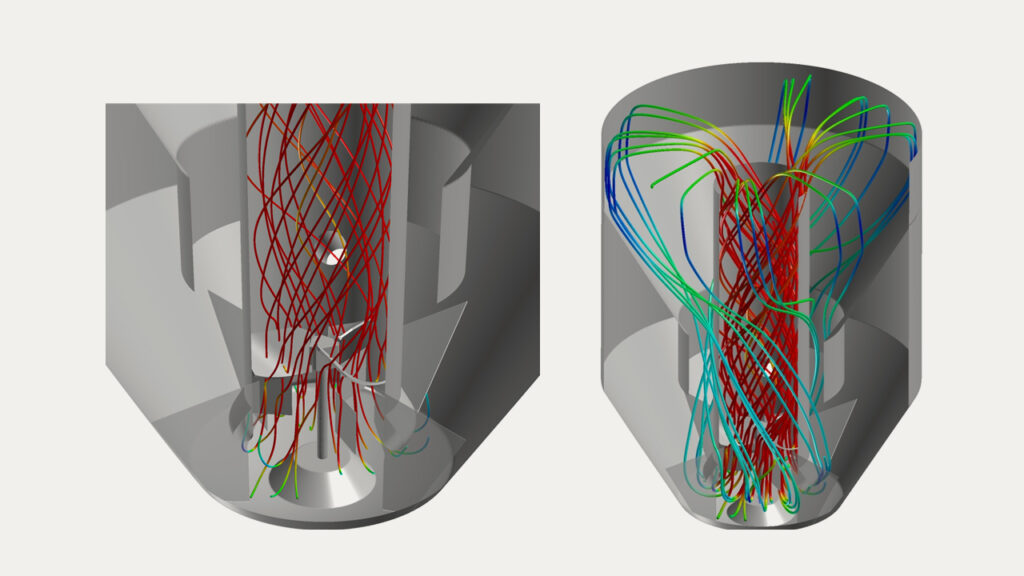

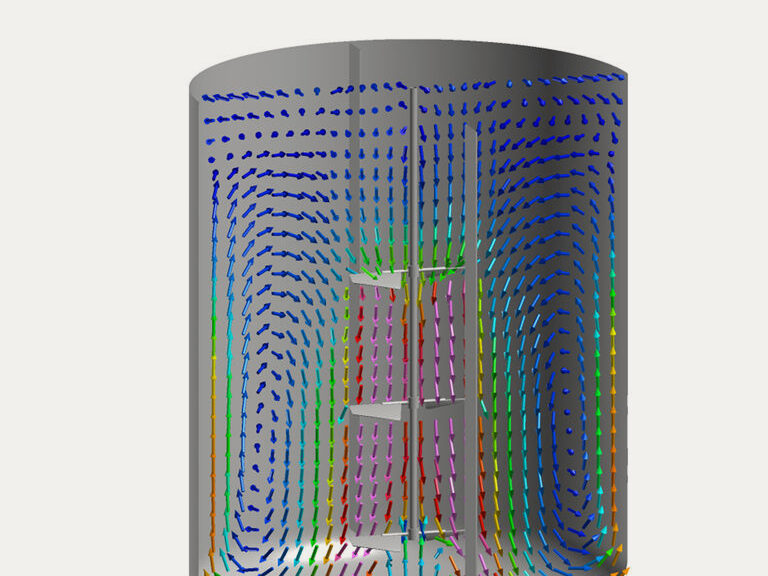

Continuously operated crystallizers are often equipped with a draft tube. Those units are called Draft Tube Baffled Crystallizer or DTBs. The impeller is located inside the draft tube and applies a directed axial flow with minimized turbulences.

The advantages of continuous operation are mainly for high capacity productions of a single product. As an example, potash is commonly processed in a DTB. Aside a high flow rate, a constant product quality and a graded separation of the crystals is required. Smaller particles should remain in the process until a certain size is reached.

EKATO has developed the TORUSJET, a three-bladed draft tube circulator, in order to significantly increase the efficiency. By observing the whole system including draft tube geometry and specially designed straightening vanes the ratio of axial flow to turbulent flow can be increased considerably. Hence less energy is required to achieve a given flow rate. This effects both investment and operational cost. As a side effect the crystals are preserved as less turbulence also means less collision and hence less chipping.

To ensure safe and long term operation it is worthwhile to check the stresses by a finite element analysis (FEA) and frequencies by a modal analysis during the design phase as the DTBs are exposed to high mechanical loads and vibrations.