EKATO

VISCOPROP

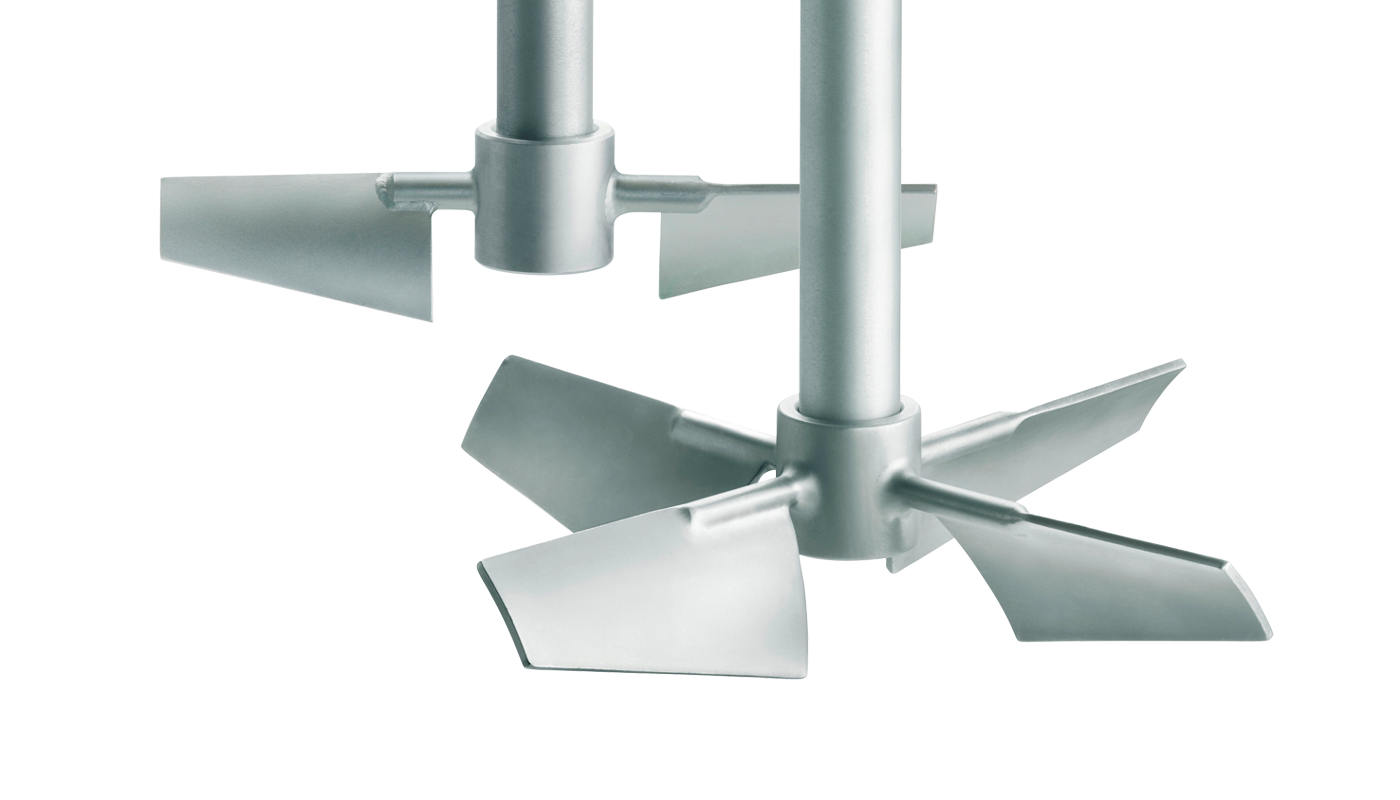

The Advanced Hydrofoil Impeller for High Mixing Efficiency

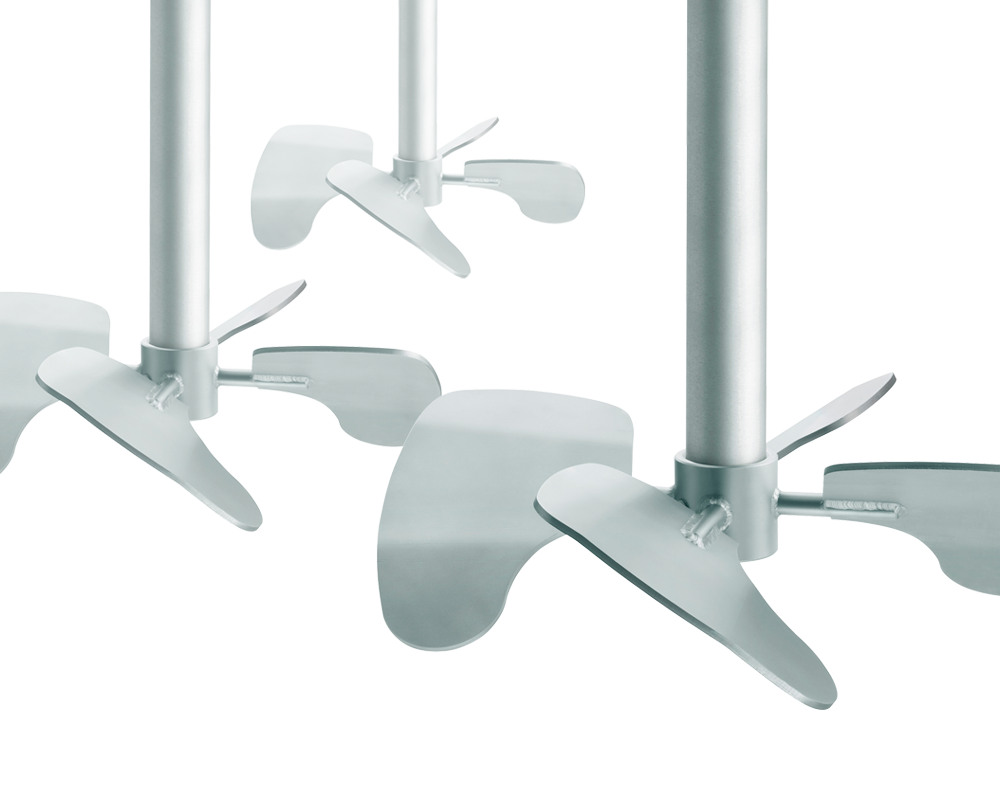

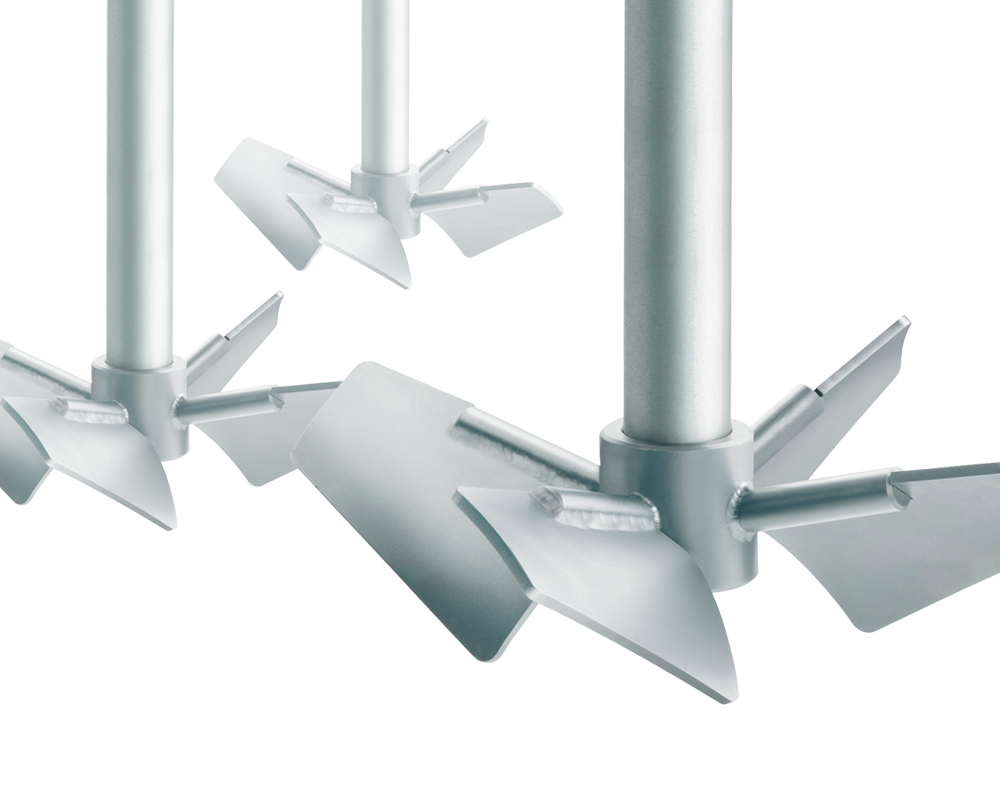

The impeller multitalent with a high mixing efficiency. Thanks to different blade angles (standard versions 25° and 53°) and number of blades, this impeller can be universally used for versatile mixing tasks: Including suspension, blending, heat transfer and dispersion, of low- to highly viscous applications.

The EKATO VISCOPROP is a universal impeller that closes the gap between axial pumping systems for turbulent, low-viscosity regimes and positive displacement mixing systems for laminar, high-viscosity regimes. Consequently, it is also used in multi-purpose equipment with frequent product changes. The EKATO VISCOPROP is not a purely axial-pumping mixing system. The standard versions have blade angles of 25° and 53°. A higher blade angle results in an increasingly radial pumping component in additional to the axial component. The VISCOPROP version with the smaller blade angle (25°) is used preferentially for low-viscosity blending and suspending tasks. The version with the higher blade angle produces a higher local energy input and a higher shear rate in the vicinity of the impeller blades. This enables homogenization of products with higher viscosities or non-Newtonian flow behavior.

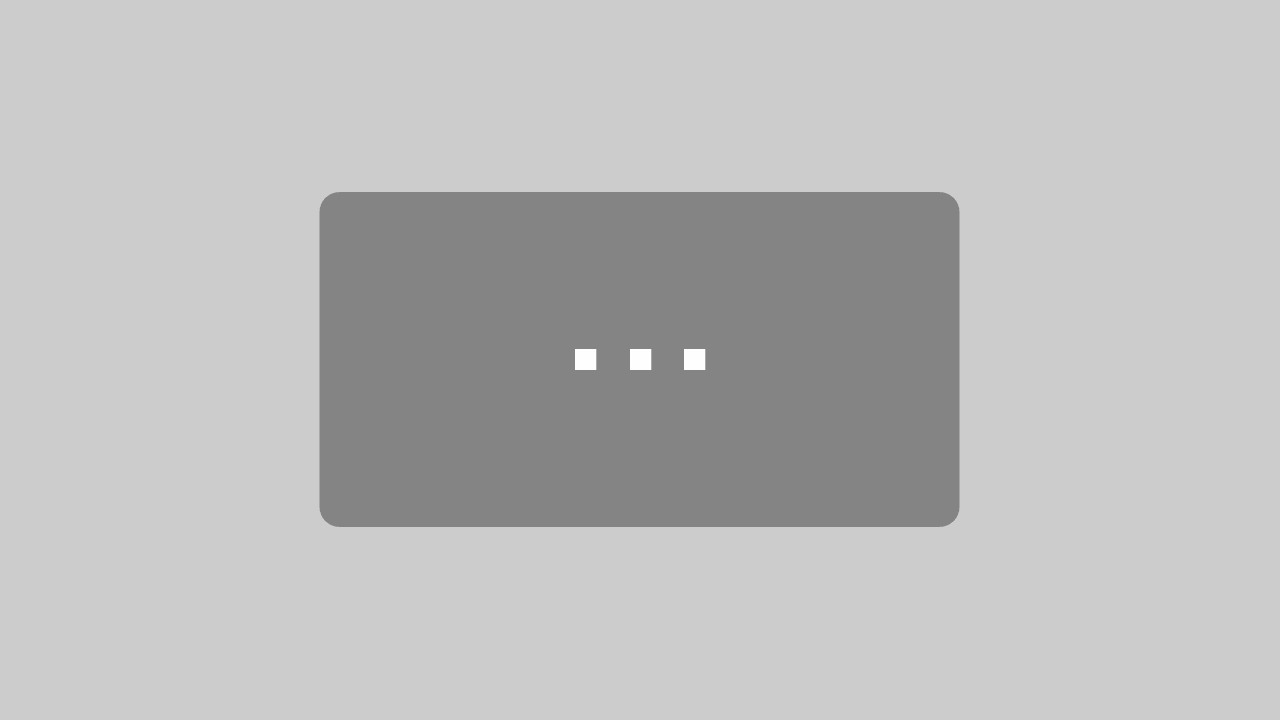

EKATO VISCOPROP 2-25 Impeller for turbulent and low viscosities

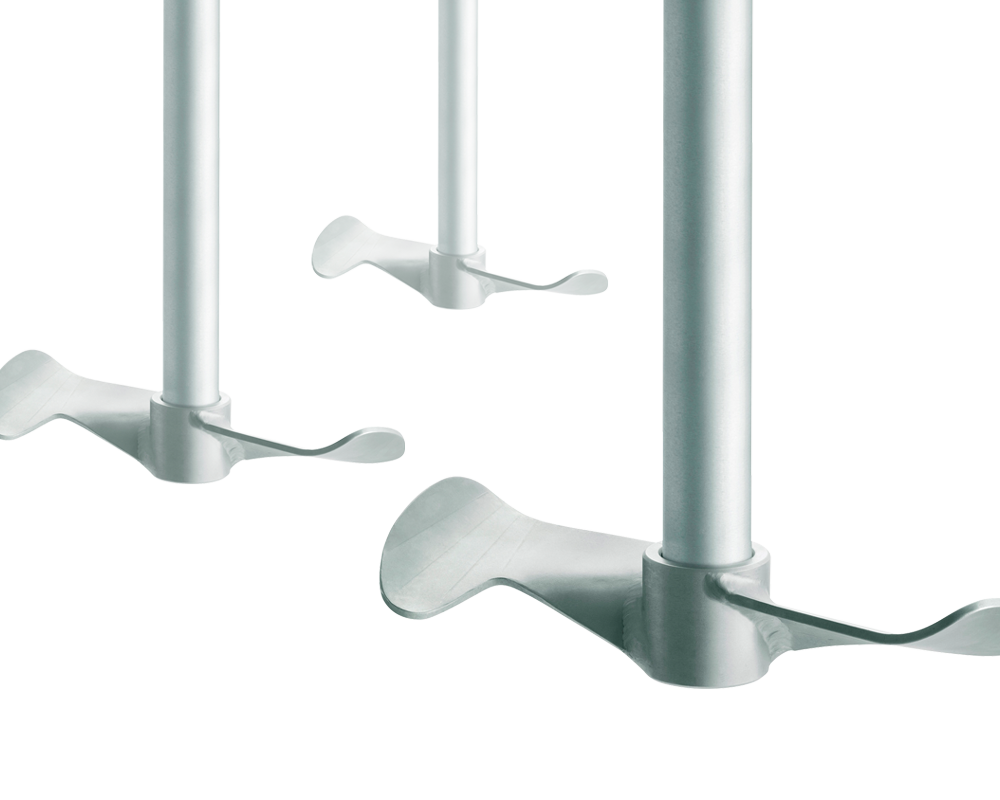

EKATO VISCOPROP 4-53 Impeller for a wide viscosity range

Features

Thanks to its advanced hydrofoil technology, the multitalent EKATO VISCOPROP is an impeller that can be universally used for multi-purpose tasks, offering:

- Outstanding mixing efficiency for low and medium viscous media

- Excellent flow velocities on the vessel bottom for the suspension of solids

- High axial flow velocities on the vessel wall for better heat transfer

- Single / multistage impeller arrangement

- Two, three or four bladed impeller design

- Customized angle of inclination