EKATO

Mixing Technology in the Cosmetic Industry

Production of Cosmetics and Personal Care Products

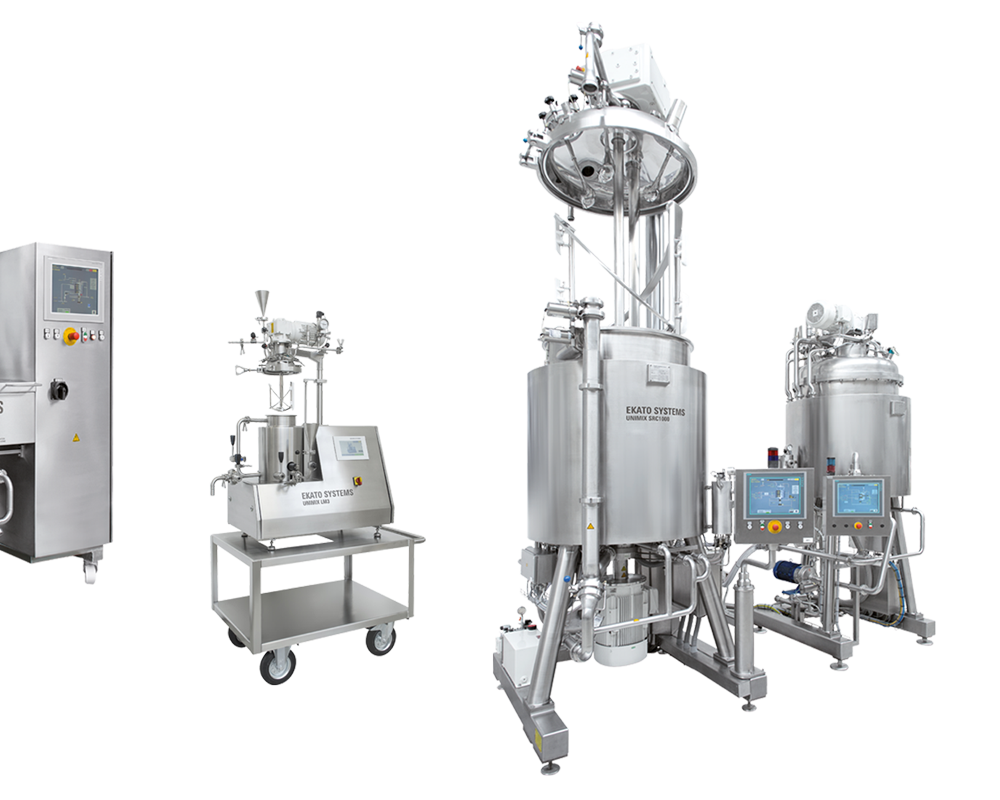

EKATO SYSTEMS offers state of the art vacuum processing units for decades, with long term experience in the cosmetic industry to meet todays and tomorrows demands. As one of the technology leader for production equipment in the cosmetic business, the EKATO product lines UNIMIX and SOLIDMIX are able to produce various product formulations.

Key Phases in the Production of Cosmetics

The production of cosmetic products is demanding different component properties to a production unit. Besides mixing and dispersing, short heating and cooling phases, degassing and different dosing methods are very important to reach the requested product quality.

The processing steps to produce ointments and creams can be divided into the following basic operations

Dosing

- Draw in liquids and solids by vacuum

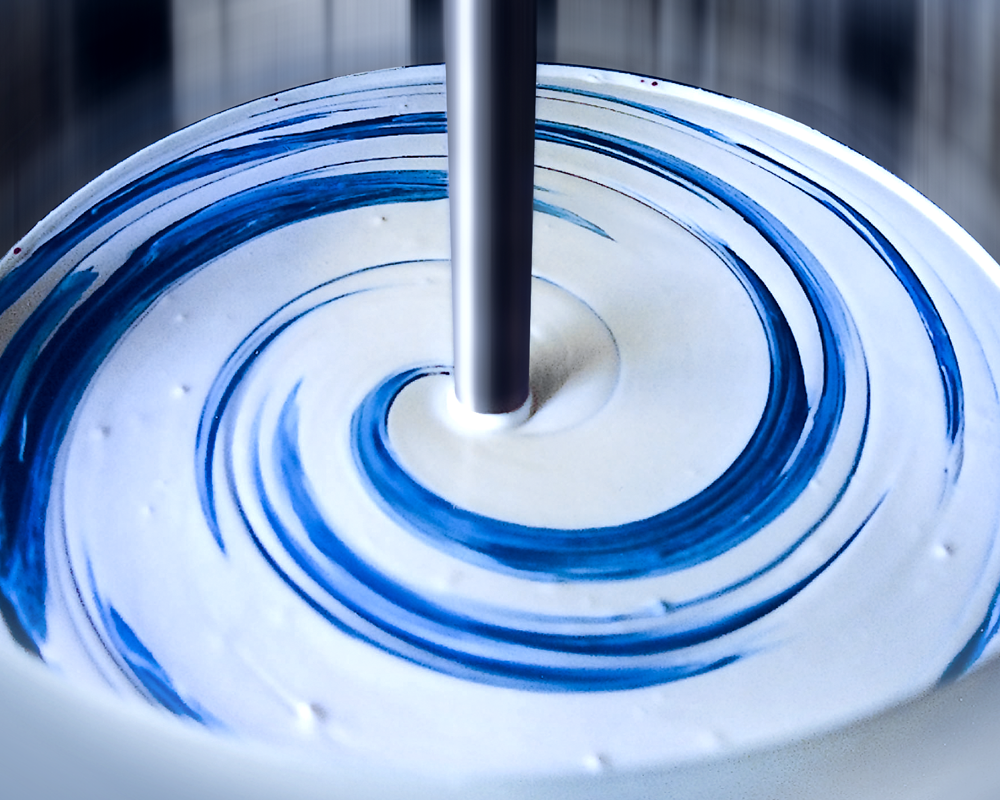

Dispersing / Homogenizing

- Dispersing of liquids during emulsification

- Dispersing of non-reactive and reactive solids

Mixing

- Incorporation of components

- Degassing of products at the end of the production process by high vacuum

Heating and cooling

- Melting of waxes and fats

- Controlled cooling

Cleaning

- CIP (cleaning-in-place)

- SIP (sterilization-in-place)

EKATO Mixers for Range of Viscosity Levels

The mixing process generally starts with the liquid having a very low viscosity but ends with a very high viscosity so that the production equipment and also the mixing and homogenizing equipment must be able to work optimally over a wide viscosity range. EKATO SYSTEMS processing units are fully equipped and, with the EKATO PARAVISC and EKATO S-JET, offer multiple options to produce all kinds of cosmetics for highest customer demands.

Typical Products which can be Produced with an EKATO UNIMIX

- Creams

- Gels

- Ointments

- Skin care

- Suspensions

- Shampoo

- Natural cosmetics

- Natural care cosmetics, with herbal ingredients

- Sun lotions

- Toothpaste

- Mascara

- Color cosmetics

- And many more