Mixing Technology in Minerals Processing

Metal Extraction Using Hydrometallurgical Processes

EKATO in Hydrometallurgy

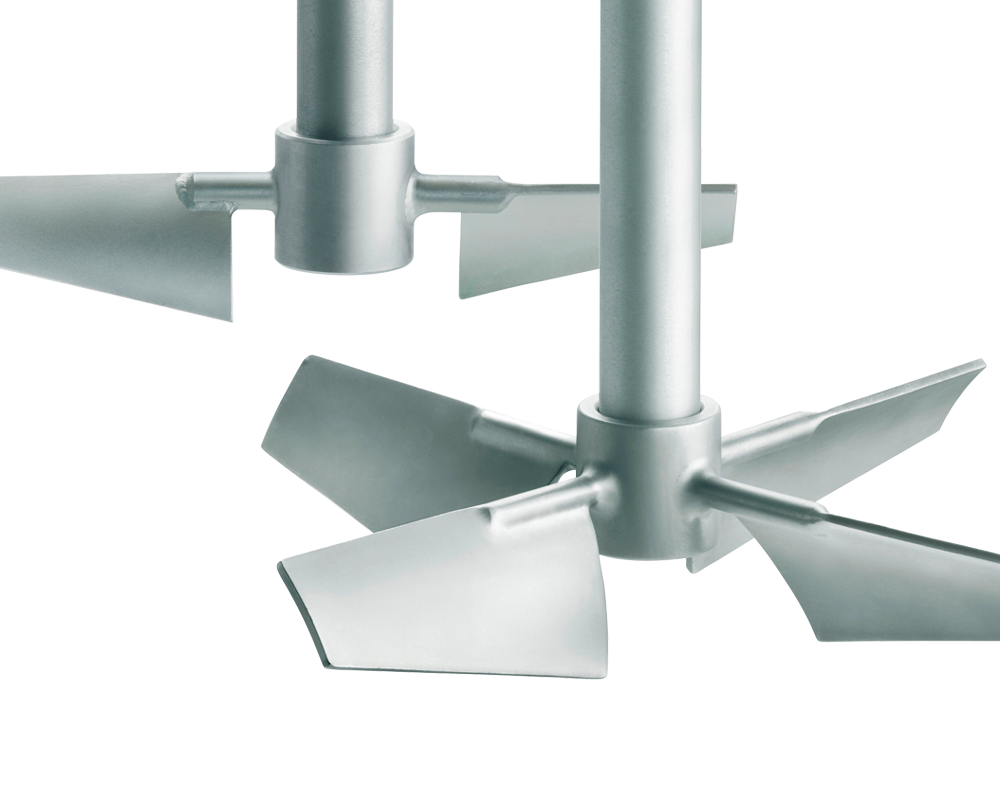

In hydrometallurgy, the three main agitator types are autoclave, atmospheric tank, and leach tank agitators. EKATO is global market leader in autoclave agitators. The company is able to draw on its vast experience to deliver customized solutions. The company offers a wide range of services, including lab testing, CFD and FEA studies, the design and manufacture of agitators, and on-site service. EKATO regularly sets new standards for gassed atmospheric tanks.

EKATO systems provide the following advantages over other technologies already on the market:

- Superior mass transfer and higher circulation rates for solid suspension mean higher yields and better results from hydrometallurgical processes.

- Higher gas yields help generate significant cost-savings.

- Lower operating costs thanks to stable operation even at very high aeration rates.

Autoclave and Tank Agitators in Hydrometallurgy

Autoclave Agitators

EKATO is the world leader for autoclave agitation technology. EKATO offers customized solutions and has valuable experience in autoclave applications worldwide. Our services are covering a wide range such as lab testing, CFD and FEA studies, design and manufacturing of agitators and site assistance.

EKATO offers a robust mechanical design and high quality manufacturing (titanium clean room for welding). Through our seal division we offer a complete range of mechanical sealing solutions and seal support systems for autoclave trains. Autoclave technology is used in hydrometallurgy when extraction by classical atmospheric leaching methods is not economical.

Autoclaves are typically horizontal vessels divided into 3 to 9 compartments or a series of single cascading vessels working at high temperature and high pressure. Extreme temperatures as well as fluctuating pressure regimes require sound designs and best quality products, ensuring maximum availability and lifetime.

Atmospheric Gassed Tank Agitators

Stirred tank reactors under continuous atmospheric operating conditions fulfill an important key function for many gassed hydrometallurgical leaching processes such as

- Bioleaching reactors

- Direct leaching

- Pre-oxidation tanks

- Cyanide detoxification

- Arsenic removal

- Iron precipitation

- Gassed chloride leach, e.g. for the nickel matte processing

- Recovery of Scandium and rare earth elements (with SO2 gas)

- Production of battery-grade lithium carbonate (with CO2 gas)

Apart from realizing “economies of scale” and implementing advances in process performance, achieving a cost optimization of such systems is a fundamental goal. Therefore EKATO has developed proprietary and unique gassing solutions the EKATO COMBIJET and EKATO COMBIJET PLUS.

Large Tanks and Leach Tank Agitators

Since the quality of ore bodies often decreases as rich resources get depleted, one trend is to process more slurry volume in one plant or module which leads to further increased vessel sizes for current and future projects. These units have to be reliably designed to ensure that the whole plant can be reliably operated. Mixing tasks can be from solids suspension duties to demanding blending of non-Newtonian slurries, if for example increased solids concentrations have to be handled.

Typical Applications are

- Leach tanks (CIL, CIP)

- Blending of non-Newtonian slurries with increased solids concentrations, e.g. autoclave feed tanks and slurry pipeline tanks

- Repulp / conditioning tanks, e.g. CCD interstage mixers, filter feed tanks,…

- Storage and surge tanks