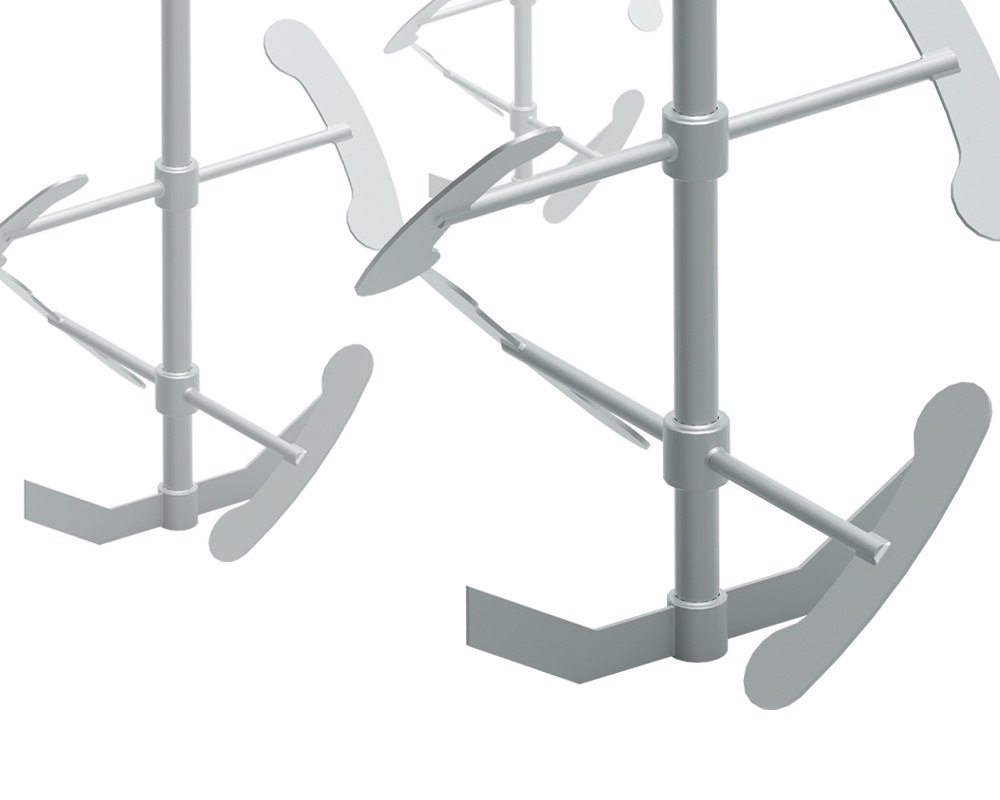

PARAVISC-COAXIAL

For Changing Low to High Viscosity Products and Demanding Requirements

Fields of Application

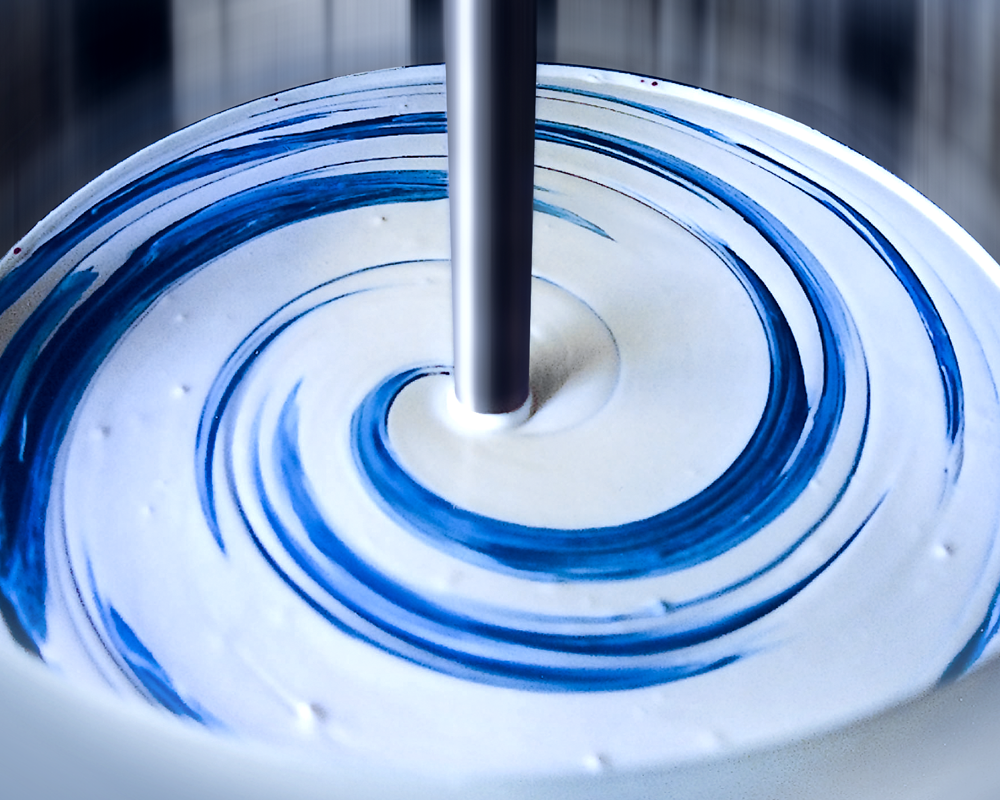

The primary tasks for a coaxial agitator are homogenizing, dispersing and heat transfer. The maximum processable product viscosities depend on the respective type of impeller, and are generally about 1 million mPa ∙ s. Coaxial impellers can therefore be used for processing steps that were previously only carried out with kneaders or extruders in which flow anomalies were unimportant. Examples for typical coaxial systems are special polymers, resin emulsions or different kinds of pastes

Operating Principle

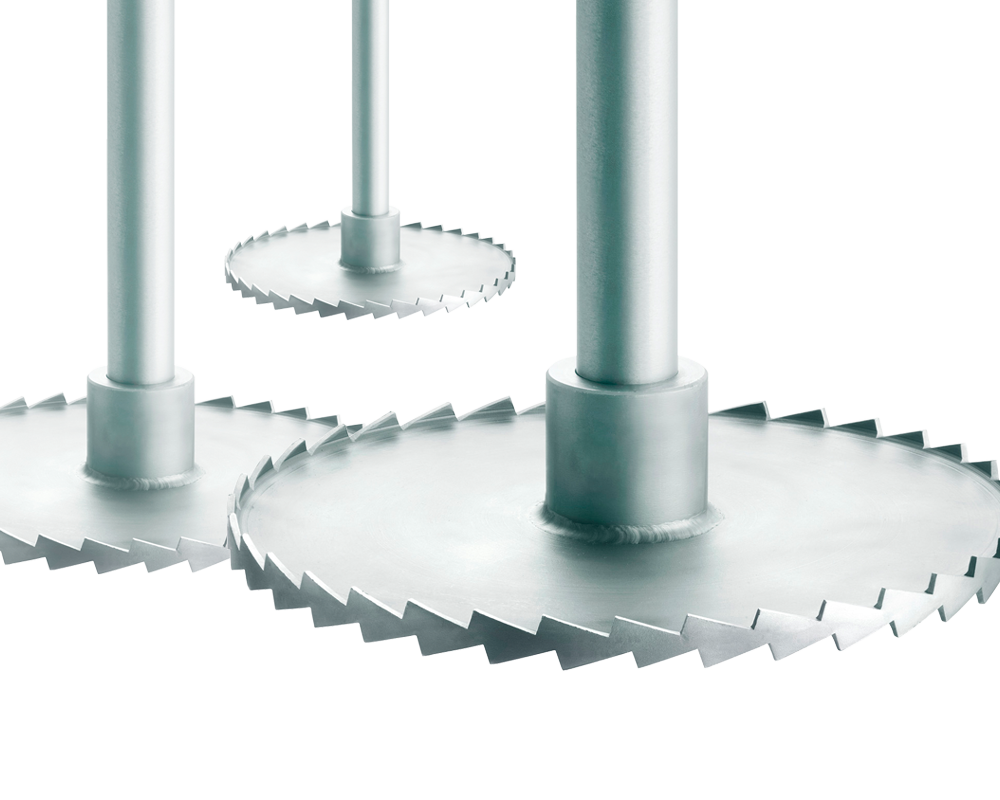

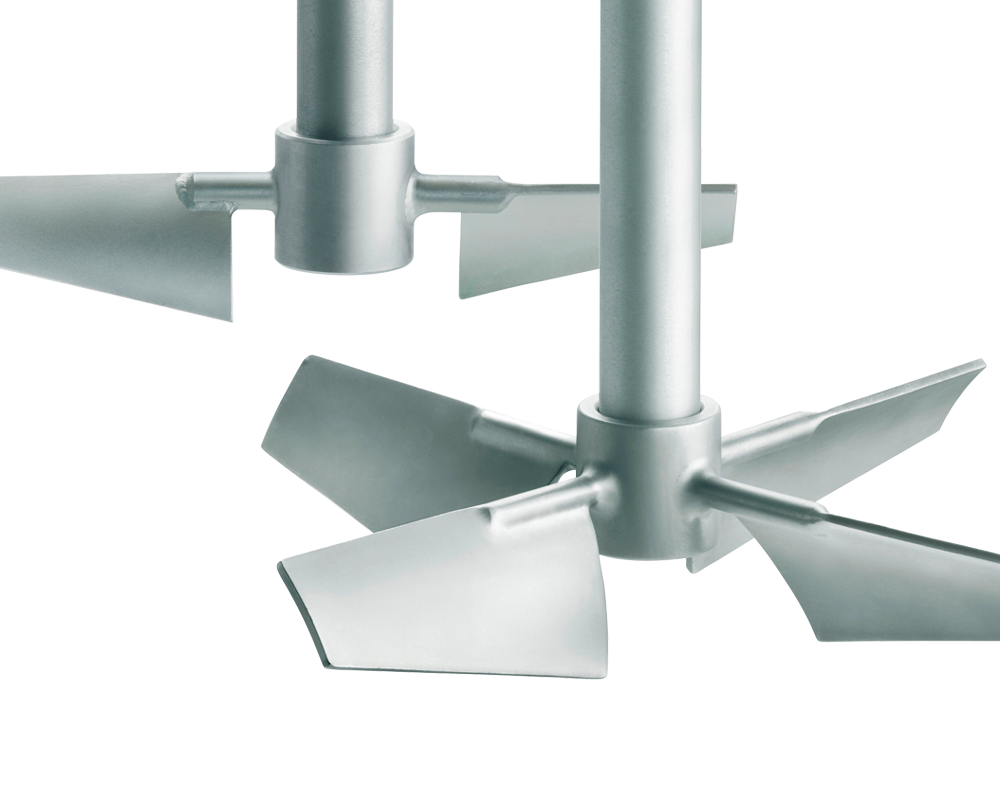

Disintegration of solids as well as dispersing and homogenizing are mainly carried out by the central agitator. Mixing tasks in low viscous process phases can also be carried out by the central impeller (e.g. EKATO VISCOPROP or Dissolver). The diameter ratio, number of stages and blades, pumping direction, tip speed and input power are specified according to the respective material properties and process data. The EKATO PARAVISC, usually rotates with a constant speed and is responsible for quick blending in the high-viscosity range. It also continuously transports product close to the vessel wall back into the zone influenced by the central impeller. In low viscous process phases, e.g. the initial phase of a batch process, the peripheral frame impeller also acts as a baffle. When diluting highly viscous masses, it prevents the formation of a thin lubricating film on the vessel wall and thus stops undesirable rotation of the entire vessel contents.

This impeller also provides particularly effective heat transfer due to the narrow clearance to the vessel wall. Additional, scraper elements keep the vessel wall clean, provide an even higher heat transfer rate and prevent localised overheating, deposits and incrustations. The combined effect of the central and frame impellers guarantees very homogeneous and high-quality products at considerably shorter blend and/or batch times.

Features

- Use of wall and central impellers operated independently of one another in both rotational directions PARAVISC ensures short mixing times and efficient heat transfer

- Central impeller enables high local power input with dissolver and extremely good surface motion and a further reduction in the blend time with Viscoprop

- Products with extreme non-Newtonian characteristics

- Ideal for multi-product plants