EKATO

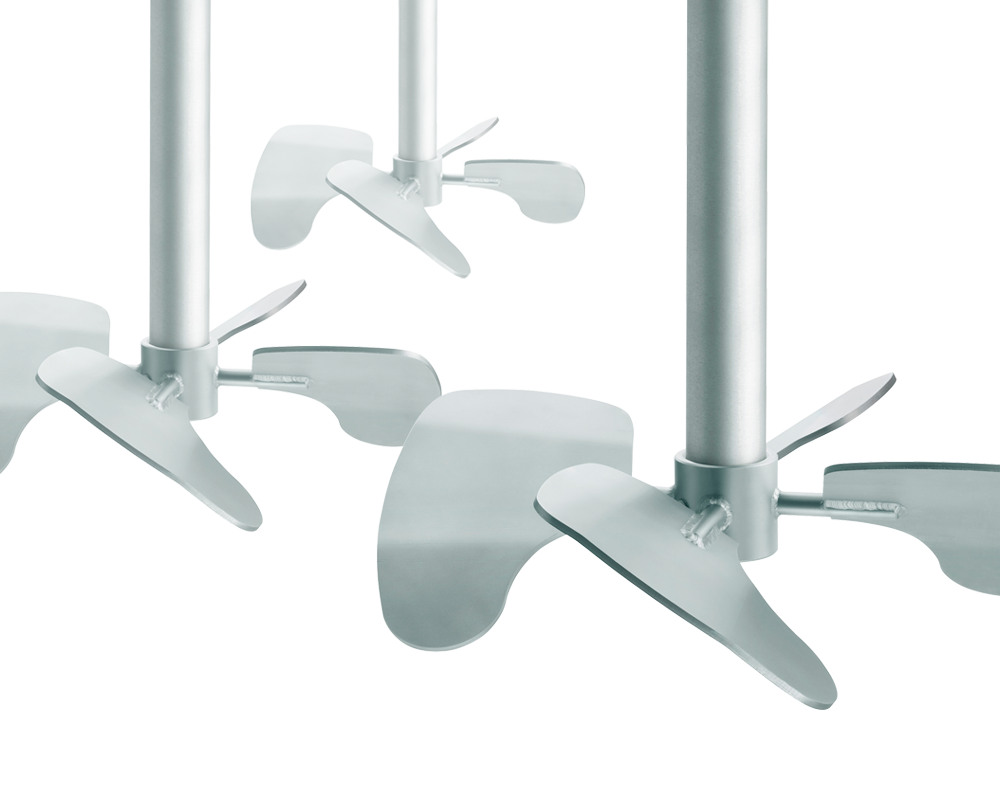

TORUSJET

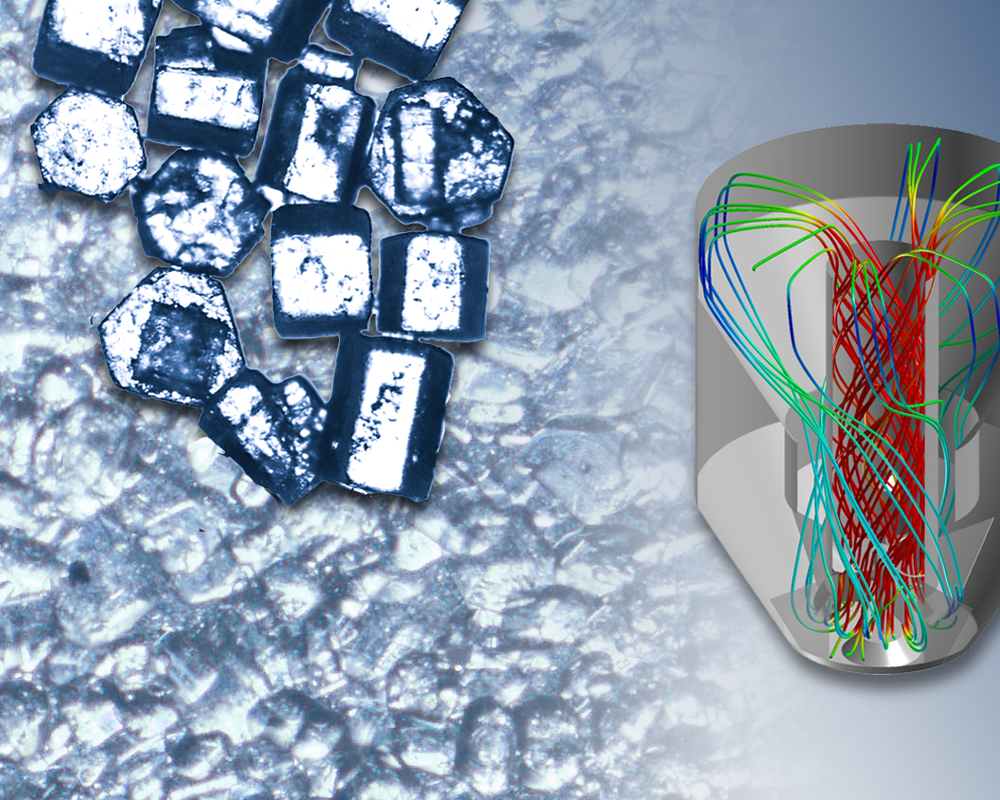

Continuous Crystallization Processes

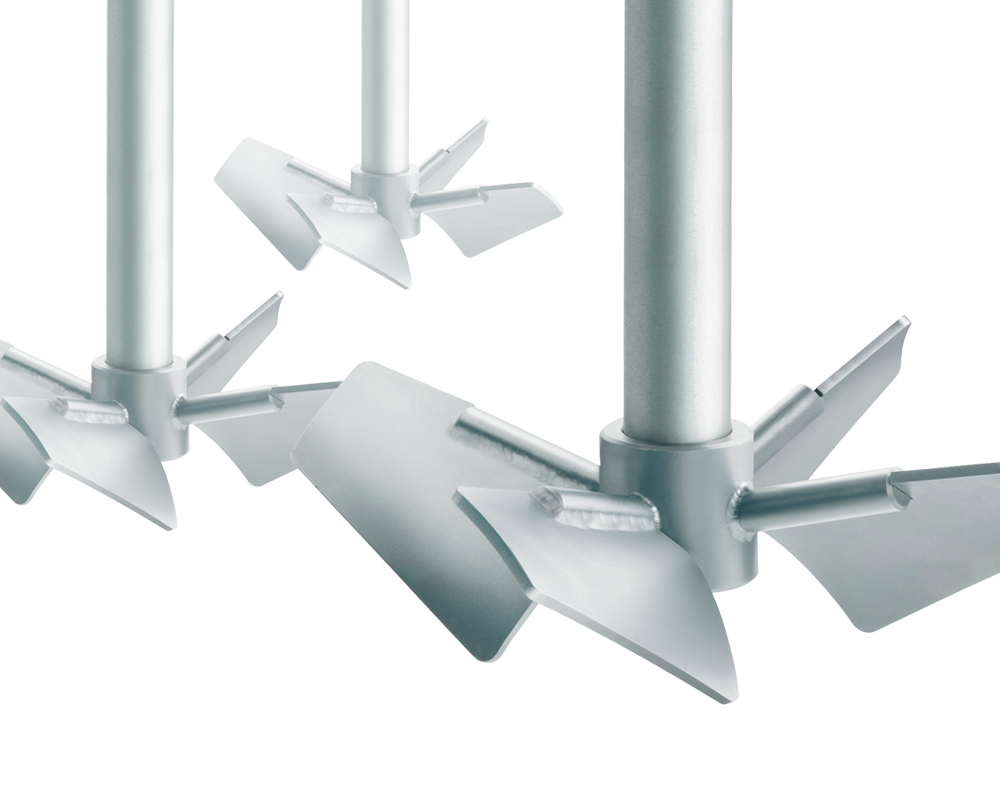

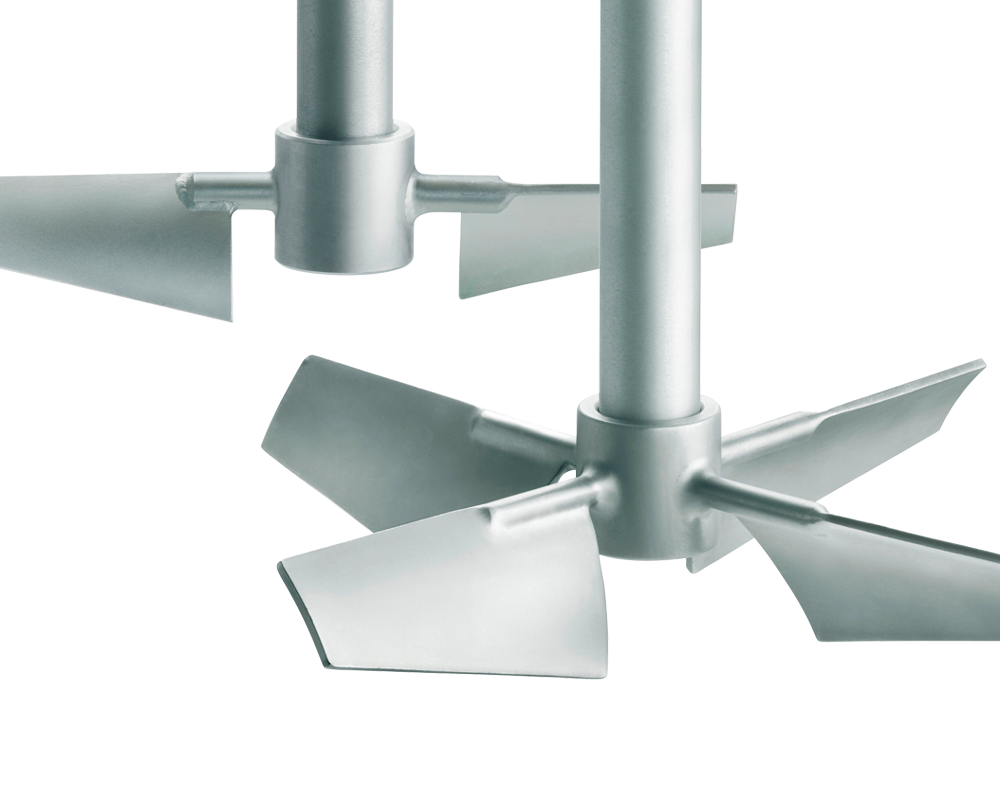

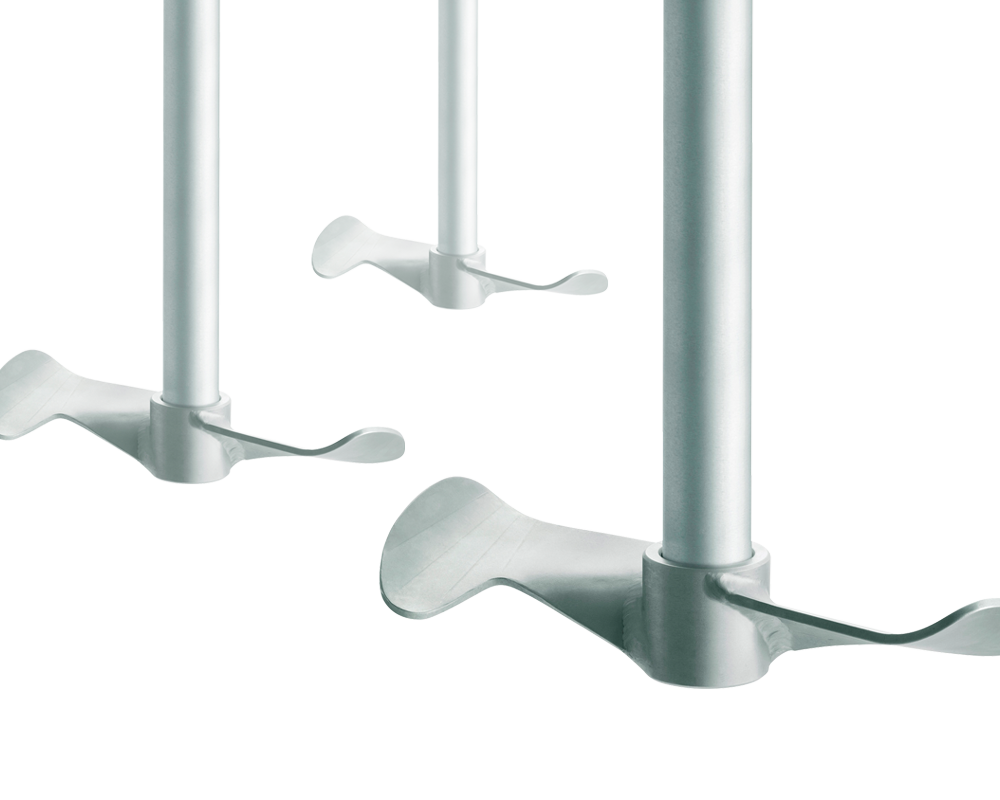

A high performance impeller developed for draft tube apparatus as in continuous crystallization processes. The flow-optimized geometry of the blades creates an exceptional axial pumping and provides a well-balanced low shear flow field.

The EKATO TORUSJET is the ideal impeller for draft tube applications like in continuous mass crystallization. Especially shaped blades minimize the shaft power for a constant flow rate and pressure drop. This provides a controlled particle formation process and allows the production of large crystals with a narrow particle size distribution.

Features

- High efficiency / high axial pumping

- Extremely high circulation rates and static heads possible

- Low particle attrition / low shear on the crystallizate

- Energy-efficient operation through the installation of geometrically optimized inlet and outlet guide vanes

- Flexible adaptation of the system to process requirements