Fermentation

Fermentation - the most versatile bio-process of humanity

What added value does EKATO provide for your fermentation process?

Your benefits when collaborating with EKATO:

- Increased productivity of biomass possible

- Enhancement of process reliability through high homogeneity

- Long-term cost savings through efficient bioreactor design

- A series optimized for cleanability to reduce contamination risks

- A comprehensive portfolio of services tailored to every project phase

Products and services in different project phases

Development + Basic Design Phase

In this phase, our customers develop the process, assess feasibility, and create initial plant concepts. We support our customers by:

- Establishing mass transfer correlations based on measurement data

- Optimizing and scaling up mass transfer (OTR / kLa)

- Scaling up agitators and vessels including heat exchangers

- Concept and basic design of the bioreactor, considering different heat transfer concepts

- Energetic optimization of the bioreactor concept (agitator, compressor)

- Conducting CFD studies, e.g., for

- Verification of low-flow zones in large fermenters

- Simulation of flow velocities between heat exchangers

- Calculation of temperature gradients in the fermenter

Detail Design Phase

In this phase, feasibility is typically demonstrated, and various disciplines are detailed in the planning. We support our customers by:

- Detail design of the fermenter agitator and vessel internals

- Verification of the mechanical integrity of the bioreactor using Finite Element Methods

- Confirmation of the existing heat transfer concept

- Consultation on cleanability of agitator components and the design of vessel internals

- Optimization of addition and measurement points in pilot and production scale

- Assistance in complying with necessary regulations and certifications such as GMP, EG1935/2004, ASME BPE, NSF H1, Kosher, Halal, etc.

Delivery and Service Phase

In this phase, the focus is on the manufacturing, delivery, and installation of agitator components, as well as the optimization of existing systems. We support our customers by:

- Manufacturing and delivering agitators according to the latest regulations

- On-site installation and commissioning of fermenter agitators at the customer’s location

- Compliant documentation of components (Good Documentation Practice)

- Customer-specific quality control and documentation before, during, and after manufacturing (FAT / SAT)

- Vibration and strength analyses of existing reactor systems to identify optimization potential using Finite Element Methods

The agitation system for industrial fermenters

The agitation system for industrial fermenters is the combination of:

EKATO PHASEJET + EKATO COMBIJET.These two different types of impellers complement each other ideally, and the advantages that this system can offer include:

- Increased productivity and product output

- Higher mass transfer

- High process reliability due to high homogeneity

The EKATO PHASEJET acts as a primary disperser, dispersing gas from the gas distributor directly upon its entry into the bioreactor. This leads to the initial reduction of gas bubbles, increasing the mass transfer surface area.

The thereby increased mass transfer surface area can result in higher productivity of microorganisms. Increased productivity, in turn, allows for shorter batch times or a higher product output.

The additional agitation stages consist of EKATO COMBIJET impellers. These are axial and radial-flow agitators with the following tasks:

- Redisperse gas

- Ensure high homogeneity through short mixing times

Through axial mixing, oxygen, heat, nutrients, and other additives are rapidly distributed in the vessel.

This ensures optimal conditions for microorganisms, thereby increasing productivity.

Mass transfer in the bioreactor

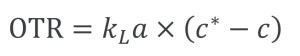

In relation to fermentation processes, the Oxygen Transfer Rate (OTR) plays a crucial role. OTR can be calculated using the following formula:

This equation allows for the quantification of oxygen transport between different phases or components of a system.

In this equation, kLa is the mass transfer capability, c* is the saturation concentration of oxygen, and c is the dissolved oxygen concentration in the fermentation broth. When scaling up fermentation processes, the usual goal is to keep the OTR constant.

Another important parameter is the Oxygen Uptake Rate (OUR). OUR describes how much of the available oxygen is taken up by the biomass. Fermenters are typically set up so that OTR = OUR.

Another relevant control parameter for fermentations is dissolved oxygen, also referred to as DO (Dissolved Oxygen). DO is usually set to a fixed value and helps control parameters relevant to fermentation.

Knowledge of the mass transfer correlation is crucial for optimizing mass transport in a specific system. In industrial fermentation processes, a better understanding of the mass transfer correlation can help increase production yield, improve product quality, and reduce energy consumption.

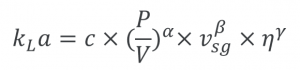

In practice, mass transfer in fermentation processes is described by empirical equations, with the kLa correlation typically being used:

The exponents α, β, and γ and the constant c depend, among other things, on the geometry of the bioreactor, the chosen agitation system, coalescence behavior, and the fermentation broth.

P represents the power input by the agitation system, V represents the volume in the bioreactor, and η represents the viscosity of the fermentation broth.

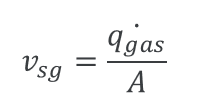

The superficial gas velocity vsg is defined as the quotient of the gas volume flow rate q ̇gas (or aeration rate) divided by the cross-sectional area A of the fermenter:

The kLa value can be influenced by agitation technology. Therefore, determining this correlation is of great importance for process optimization and the scale-up of fermenters.

When optimizing the kLa value through agitation technology, it is noticeable that the agitation system usually affects only one measurable variable, namely the power input P. The higher the power input P of the agitation system, the higher the kLa value, and thus the OTR.

Alternatively, increasing the air-gas flow q ̇gas can lead to an increase in superficial gas velocity vsg to optimize mass transfer. In practice, this is achieved by using a more powerful compressor.

However, it is important to note that increasing the air-gas flow q ̇gas can reduce the efficiency of agitation systems.

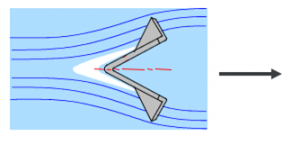

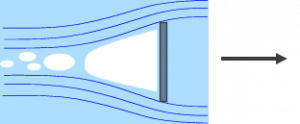

This is because a higher aeration rate forms larger gas bubbles at the agitator blade, leading to reduced flow resistance and thus less power being introduced from the agitation system into the medium. Due to the blade geometry of the Rushton turbine, it is particularly susceptible to power losses under aeration, as shown in the following figure:

This means that the agitation system, due to its geometry and the amount of gas present, cannot always introduce agitation power into the agitation medium.

With the EKATO agitation system, the power drop under aeration is very low, thanks to the optimized blade geometry of the respective impellers.