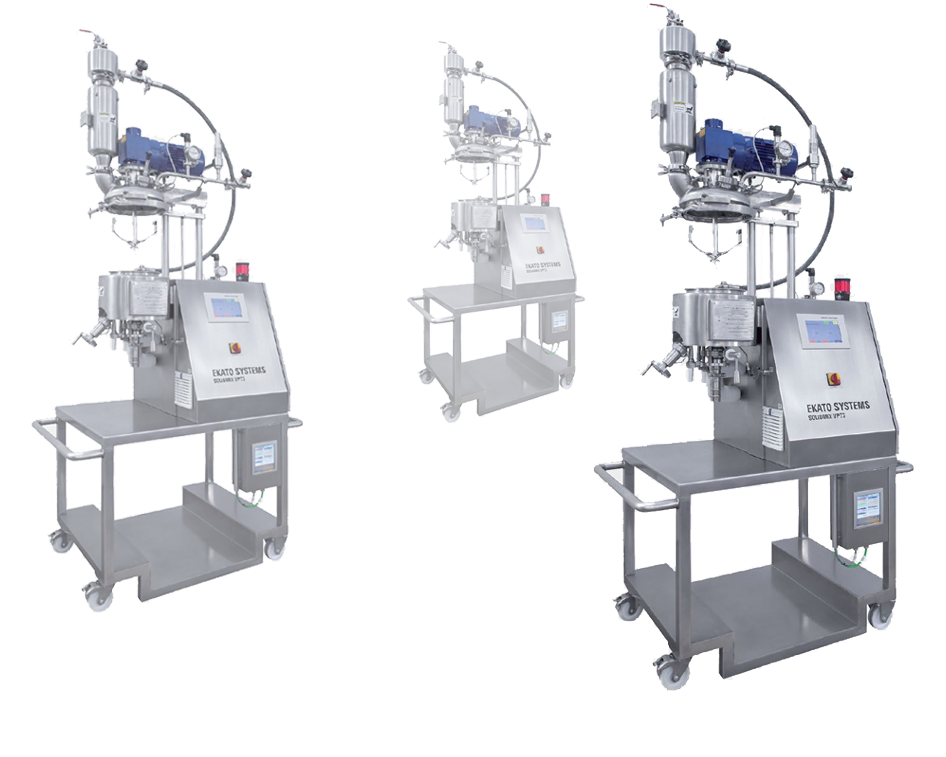

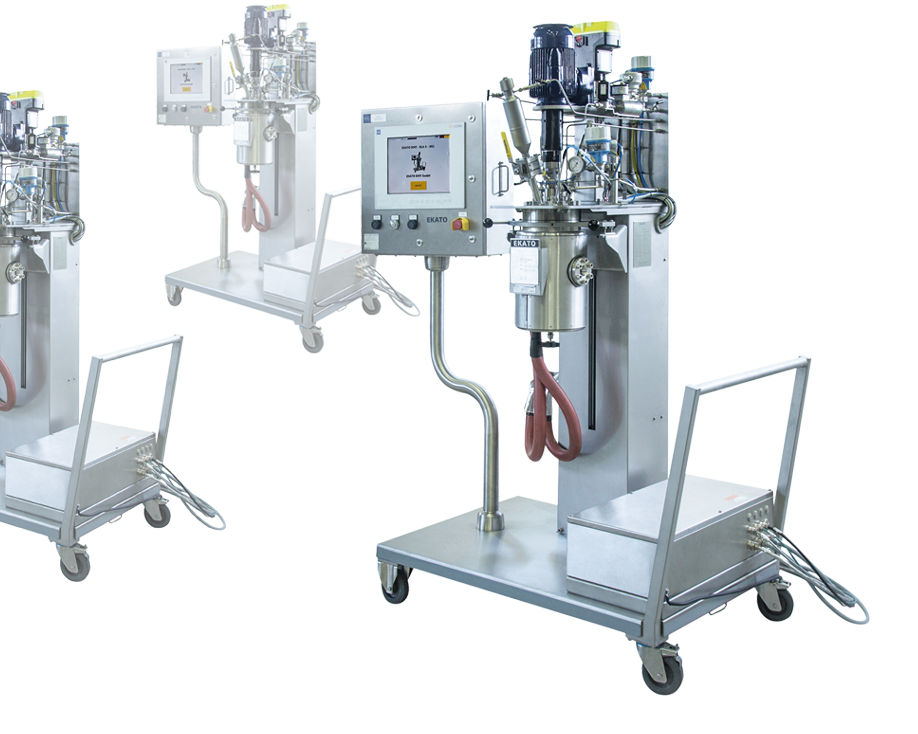

Pilot Plants

When developing new processes, the chemical engineer determines the basic conditions and recipes for the process. This laboratory data is generally not sufficient enough to design the production plant. The interaction of chemistry, physical parameters and instrumental boundary conditions in complex processes is usually determined in pilot plants. In EKATO’s laboratories, a number of lab and pilot plants are available for carrying out such investigations.